Meats and Sausages

Ives-Way Can Sealer - Adjusting for Various Can Sizes

To seal can properly we have to provide the right amount of pressure in two dimensions:

- Horizontal pressure between the chuck and seaming rollers.

- Vertical pressure between the chuck and the turntable.

Each can diameter requires a corresponding chuck as the chuck must hold and spin the lid of the can. The chuck must also provide correct pressure against seaming rollers. The pressure is controlled by adjusting the seaming rollers assembly. The 3-hole nut of the pressure assembly has 3 holes and each of them can accommodate the seaming roller's screw.

- No. 1 hole is nearest the chuck so it will be used for smaller diameter cans.

- No. 2 hole in the middle so it will be used for medium diameter cans.

Inserting the seaming roller's screw into the right hole adjusts roughly adjusts pressure between the can and seaming rollers in horizontal plane. The fine adjustment is achieved by adjusting seaming rollers with wire gauge.

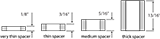

Turntable - Spacers - Table Extension

- Ives-Way Products, Inc.

- PO Box 70

- Round Lake Beach, Illinois 60073

- Phone: (847) 740-0658