Meats and Sausages

Stuffing

Choosing the right stuffer is important because stuffing is labor-intensive. A commercial meat plant, a little butcher shop, and a home sausage maker have different requirements for stuffing sausages. Meat plants need a machine to stuff, link, and portion sausages in one cycle. Sausages must be the same length and weight, otherwise it would be impossible to estimate costs and run the business. Such piston stuffers are very expensive and can stuff thousands of pounds of sausage in one hour. The piston is powered by hydraulic pressure and the stuffer is controlled with a foot or a knee.

Butcher shops do not care much about linking and portioning sausages as a salesperson weighs each order. The experienced sausage maker can manually link sausages quite fast. Drawing on his experience, he can estimate the weight of one foot of a sausage of a particular diameter. What is important is that the stuffer performs faultlessly and is easy to operate and maintain. Such stuffers can be manually operated or hooked up to a motor. Most shops use manually operated piston stuffers or small hydraulic stuffers.

The most popular method employed by home sausage makers is using a hand-cranked grinder with sausage tube attachments. This is a labor-consuming operation, but it can be handled by one person when making a few pounds of sausage. For large orders, two people usually work together; one person operates the grinder/stuffer, and another links the sausages. Recently, many manually cranked piston stuffers (5-20 lbs. capacity) have entered the marketplace. They are inexpensive and reliable, and some of them can be motorized.

Grinder with an Attached Stuffing Tube

The original stuffing technique was simple: the casings were slid over one end of a suitable tube or a funnel, and the meat was pushed with fingers inside. There still exists a Polish sausage named “palcówka” ("palce" means fingers) that was done that way.

The knife and plate are removed from the grinder, and the auger pushes meat into the stuffing tube. It wobbles a bit as it is not held in place by the grinder plate, which was removed. The optional spacer will provide support for the auger, and the wobling will stop. The main drawback of this arrangement is that it requires two persons to stuff the casing. One inserts meat into the mouth of the grinder and rotates the crank. The second operator holds the tube and casing with his hand controlling the speed and and amount of meat that can flow into the casing.

Horn Stuffer

There is a small (3-5 lbs.) horn stuffer that looks cute, but, from the practical point of view, is not much better than the hand grinder with tubes. It still requires two people to do the stuffing, though a strong person might do it alone. It is our opinion that a serious hobbyist should invest in a vertical piston stuffer ,which will make stuffing faster and more enjoyable. The money saved by not buying an electric grinder can be reinvested into a purchase of a piston stuffer. By all means, if you can afford it, buy all top-of-the line industrial automated equipment, but keep in mind that a manual grinder is an incredibly efficient device that can be successfully deployed in any production that requires 20 pounds or less of sausage.

Photos courtesy The Sausagemaker, Buffalo, NY

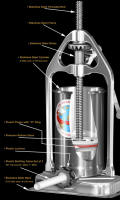

Manual Piston Stuffer

There is a little built-in air valve into the piston to release air pressure that normally will be pushed inside the sausage, creating air pockets; on the bottom side of the cylinder, there is an opening that accepts different sizes of sausage tubes. One person can easily control the casing and sausage speed with one hand and turn the handle that moves the piston down with the other.

Photos Courtesy The Sausage maker, Buffalo, NY

Hydraulic Piston Stuffer

Photos courtesy Koch Equipment, Kansas City, MO.