Meats and Sausages

Cooling Meat Products

The following standards come from the Food Safety and Inspection Service (FSIS), United States Department of Agriculture (USDA, June 1999):

Compliance Guidelines for Cooling Heat-Treated Meat and Poultry Products (Stabilization)

It is very important that cooling be continuous through the given time/temperature control points. Excessive dwell time in the range of 130° to 80°F is especially hazardous, as this is the range of most rapid growth for the clostridia. Therefore, cooling between these temperature control points should be as rapid as possible.

- During cooling, the product’s maximum internal temperature should not remain between 130°F and 80°F for more than 1.5 hours nor between 80°F and 40°F for more than 5 hours. This cooling rate can be applied universally to cooked products (e.g., partially cooked or fully cooked, intact or non-intact, meat or poultry) and is preferable to (2) below.

- Over the past several years, FSIS has allowed products to be cooled according to the following procedures, which are based upon older, less precise data: chilling should begin within 90 minutes after the cooking cycle is completed. All products should be chilled from 120°F (48°C) to 55°F (12.7°C) in no more than 6 hours. Chilling should then continue until the product reaches 40°F (4.4°C); the product should not be shipped until it reaches 40°F (4.4°C). This second cooling guideline is taken from the former (“Requirements for the production of cooked beef, roast beef, and cooked corned beef”, 9 CFR 318.17(h)(10). It yields a significantly smaller margin of safety than the first cooling guideline above, especially if the product cooled is a non-intact product. If an establishment uses this older cooling guideline, it should ensure that cooling is as rapid as possible, especially between 120°F and 80°F, and monitor the cooling closely to prevent deviation. If the product remains between 120° F and 80° F for more than one hour, compliance with the performance standard is less certain.

- The following process may be used for the slow cooling of ready-to-eat meat and poultry cured with nitrite. Products cured with a minimum of 100 ppm ingoing sodium nitrite may be cooled so that the maximum internal temperature is reduced from 130 to 80° F in 5 hours and from 80 to 45° F in 10 hours (15 hours total cooling time).

This cooling process provides a narrow margin of safety. If a cooling deviation occurs, an establishment should assume that their process has exceeded the performance standard for controlling the growth of Clostridium perfringens and take corrective action. The presence of the nitrite, however, should ensure compliance with the performance standard for Clostridium botulinum.

To make it simpler, the cooked product should pass the “danger zone” (40-140° F, 4 - 60° C) as fast as possible. The most dangerous part of this range is between 130 and 80° F (54-27° C) and should be passed within 1.5 hours.

In cafeteria buffets cooked foods are held at 140° F (60° C) or higher. Holding foods at such temperatures has detrimental effects on their quality. If they are to be stored for longer periods, hey must be held at < 40° F (4° C).

From FSIS Directive 7117.0

- Heat-resistant food-poisoning bacteria can grow from 38°F up to approximately 125° F; however their range of rapid growth is from approximately 80°F to 125° F. Thus, cooling product quickly through the rapid growth range is more important than cooling through the slow growth range.

- The rate of heat transfer (cooling rate) from the product’s center to its surface is directly proportional to the difference in temperature between those two points. Thus, as the product temperature approaches the coolant temperature, the cooling rate diminishes.

- Traditional cured products, containing high amounts of salt and nitrite, together with low moisture content, are more resistant to bacterial growth than similar newer products; some are even shelf-stable. Thus, rapid cooling of these traditional products is not always necessary. However, manufacturers are making fewer products of this type today. Instead, to meet present consumer tastes, most of their cured products contain less salt and more moisture. These changes minimize the inhibitory effect of added nitrite and increase the need to rapidly cool these products.

A question may arise as to why not to place a cooked product straight in a refrigerator? Well, you could, and nothing will happen to your product, but you may lose your expensive refrigerator. At first, when the hot product is placed in a refrigerator, the initial cooling rate is fast. How fast it is depends on the the temperature of the hot meat and the temperature inside the refrigerator. Both the temperature of the food and the temperature of the refrigerator will drop lower and the cooling rate will slow. If a large amount of hot food is placed inside, it may severely test the capacity of the refrigerator to do its job. The temperature of the refrigerator and the meat will come closer together, and other foods will start warming up. For those reasons, it is recommended that the food is pre-cooled.

A home unit is designed to hold foods at 36-40° F (2 - 4° C) and not to cool large amounts of very hot products. For this purpose, we have industrial blast chillers with large-capacity compressors that blow cold air over the meats and chill them quickly. At home, the best solution is to shower or place them briefly in cold water. They may be kept in cold water (or ice bath) even longer, but they should be placed in plastic bags first to prevent unnecessary loss of meat flavor or salt migration. Then, when the product goes into the refrigerator, there should be some space around it to facilitate cooling.

Cooling Sausages

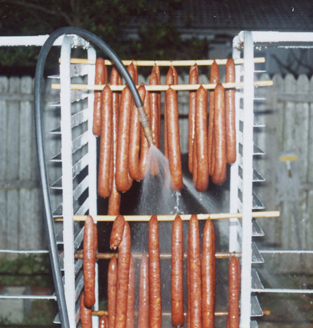

The sausages should be showered with cold water after cooking. However, a brief shower with hot water cleans the surface from any soot or grease accumulation. A hot spray is applied by commercial producers and very seldom by hobbyists. At home, a cold shower is normally practiced. As most smokehouses are located outside of the house, the common method employs the use of a garden hose. Sausages cooked in water should be transfered to another vessel filled with cold water (50-60º F, 10-15º C). Cooling sausages with water offers the following advantages:

- Cleans the surface from grease.

- Extends product’s shelf life.

- Decreases time of air cooling, which subsequently follows.

Cooling smoked sausages

Sausages should remain at temperatures between 130º - 50º F (55º - 10º C) for the shortest time possible as this temperature range facilitates the growth of bacteria. Although bacteria have been killed during the cooking process, new bacteria are anxious to jump into the sausage's surface. Cooling time depends on the diameter of the product, but it may be estimated as:

- Small diameter sausages such as frankfurters - 5-10 min.

- Large diameter sausages - 15-20 minutes.

When the sausages have cooled down, rinse them briefly with hot water to wash down any grease that might have accumulated on the surface. Then, they should be wiped off with a moistened cloth until they are clean and dry. Once the temperature drops below 68° F (20° C) it is safe to hang sausages for air cooling. The sausages will develop a darker color and better looks but may also become more shriveled, though some shriveling is normal. The solution is to poach them again for 30-60 seconds with hot water (194° F, 90° C) and then cool them as before.

During this cooling/drying process, a smoked sausage will further improve its shine and color and develop a darker shade of brown. Some call it “blooming,” Sausages should be hung in a dark place, Remember to protect the floor from any grease dripping down. After that, the sausage can be refrigerated.