Meats and Sausages

Metal Cans

The number of cans on the market is overwhelming and choosing the right can may be an intimidating task for a newcomer. Metal cans come in different shapes and sizes. The can sizes used in industry in the U.S.A. are derived from nominal outside dimensions. While such dimensions may be expressed in inches, the custom is to use a conventionalized method in which three-digit numbers are used to express each dimension. The first digit indicates the number of whole inches in a dimension, and the second and third digits indicate the fractional inches as sixteenths of an inch. Thus:

- 211 x 400 means 2-11/16 x 4 inches

- 307 x 409 means 3-7/16 x 4-9/16 inches

- 404 x 414 means 4-4/16 x 4-14/16 inches

In oval cans, outside dimensions are used, the dimensions of the opening stated first, followed by the height. The inches and sixteenths of an inch system is the same as with round cans. An example: 402 x 304 x 300, means that the oval opening is 4-2/16 x 3-4/16 inches and the height is 3 inches. Metric system is much simpler and the sizes are defined in millimeters, for example:

- round cans - 73 x 55 mm, 99 x 63 mm, 99 x 119 mm

- oval cans - 90 x 103 x 217 mm

Capacity, of course, is defined in milliliters.

There are cans which are suitable for certain applications, for example beverage cans, beer cans, soup cans or meat and fish cans. Food cans are lined up with enamel coating inside to prevent any reactions between metal and food which may affect the flavor of the product. The most popular can is the basic round can, constant diameter, parallel walls, which is a cylinder. However, the tapered cans are of more interest to a homeowner. The tapered can has tapered body walls so that the diameter of the two ends is different. The advantage of this design that the cans can be nested during shipping, resulting in smaller packages and lower costs. They can also be stacked easily in storage. A hobbyist must consider the can size he intends to use with the size of the can sealer that can seal it. Metal cans are expensive when bought by the dozen, however, the price drastically drops when ordering a few hundred.

| Industry Can Name | Capacity (Water) | Can Size | Diameter in Inches | Height in Inches | Size in mm |

|---|---|---|---|---|---|

| 202 | 3.60 oz | 202x204 | 2.13 | 2.25 | 54.0x57.2 |

| 202 | 4.80 oz | 202x214 | 2.13 | 2.88 | 54.1x73.2 |

| 6 Z | 6.00 oz | 202x308 | 2.13 | 3.5 | 54.2x89.0 |

| 4 oz Mushroom | 7.15 oz | 211x212 | 2.69 | 2.75 | 68.3x69.9 |

| 8 Z Short | 7.90 oz | 211x300 | 2.69 | 3.00 | 68.4x76.3 |

| 8 Z Tall | 8.6 oz | 211x304 | 2.69 | 3.25 | 68.4x82.6 |

| 1 (Picnic) | 10.9 oz | 211x400 | 2.69 | 4.00 | 68.4x101.7 |

| 211 Cylinder | 12 oz | 211x214 | 2.69 | 4.88 | 68.4x124.0 |

| 8 oz Mushroom | 15 oz | 300x400 | 3.00 | 4.00 | 76.2x101.6 |

| 300 | 15.2 oz | 300x407 | 3.00 | 4.44 | 76.2x112.7 |

| 300 Cylinder | 21.8 on | 300x509 | 3.00 | 5.56 | 76.2x141.3 |

| Pint, salmon, tapered | 16 oz | 301x408 | 3.06 | 4.50 | 77.8x114.3 |

| 1 Tall | 16.7 oz | 301x411 | 3.06 | 4.69 | 77.8x119.2 |

| 303 | 16.8 oz | 303x406 | 3.19 | 4.38 | 81.0x111.3 |

| 303 Cylinder | 21.8 oz | 303x509 | 3.19 | 5.56 | 81.0x141.3 |

| 1/2 lb Tuna | 5 oz | 307x113 | 3.44 | 1.81 | 87.4x46.0 |

| 1/2 Pint (1 lb), tapered | 7.75 oz | 307x200.25 | 3.44 | 2.00 | 87.4x51.2 |

| 2 Vacuum | 14.7 oz | 307x306 | 3.44 | 3.38 | 87.4x85.9 |

| 2 | 20.5 | 307x409 | 3.44 | 4.56 | 87.4x115.9 |

| Jumbo | 25.8 oz | 307x510 | 3.44 | 5.63 | 87.4x143.0 |

| 2 Cylinder | 25.8 | 307x512 | 3.44 | 5.75 | 87.4x146.1 |

| 1.25 | 13 oz | 401x206 | 4.06 | 2.38 | 103.2x60.5 |

| 2.5 | 29.8 | 401x411 | 4.06 | 4.69 | 103.2x119.2 |

| 3 Vacuum | 26.6 oz | 404x307 | 4.25 | 3.44 | 108.0x87.4 |

| 3 | 35 oz | 404x414 | 4.25 | 4.88 | 108.0x124.0 |

| Tall No. 3 | 51.70 oz | 404x700 | 4.25 | 7.00 | 108.0x177.8 |

| 5 | 59.10 oz | 502x510 | 5.13 | 5.63 | 130.3x143.0 |

| 5 Squat | 68.15 oz | 603x408 | 6.19 | 4.50 | 157.2x177.8 |

| 10 (Gallon) | 109 oz | 603x700 | 6.19 | 7.00 | 157.3x177.8 |

| 12 (Full gallon) | 138 oz | 603x812 | 6.19 | 8.75 | 157.3x222.3 |

- The capacity of can is given in ounces of water at 6° F, 20° C.

- 1 US fluid ounce = 29.57 ml

- 1 inch = 25.4 mm

Metal can sizes used in industry in the U.S.A. are derived from nominal outside dimensions. Measurements are made of the empty round can before seaming on the packers' end. Using the outside diameter of the No. 2 can for calculating cylinder volume will tell us that the can is able to hold 23.5 liquid ounces. However, in reality the can will hold only 20.5 ounces of water. Using the inside diameter will provide the correct number. There are can-shaped containers made from aluminum foil and plastic laminates, there are rectangular-shaped cans and retortable pouches. Cans with easy-to-open rings on the lid are very popular. They all, however, require specialized equipment which is not available to a hobbyist. For home canning it is difficult to beat a round cylindrical can.

| mm | 52 | 65 | 73 | 83 | 99 | 105 | 127 | 153 | 168 | 176 |

| USA | 202 | 211 | 300 | 307 | 401 | 404 | 502 | 603 | 610 | 700 |

Metric size cans use the inside diameter to describe the can. For example No. 2 can, 307 x 409 converts to 87 (outside dia) x 115 mm, however, it is classified as 83 (inside dia) x 115 mm can in Europe. Remember that every time you use a can with a different diameter, you need a different size chuck in your sealer. When buying a sealer you have to specify the size of the can you will be sealing and the sealer comes with this size chuck and spacer pre-installed. Let's assume you have a 225 model sealer equipped for No. 2 can (307 diameter) and you decide that you want to can your salmon in smaller No. 1 cans (211 diameter). Well, you have two options: buy another expensive 225 sealer equipped for No. 1 can, or buy an additional chuck for No. 1 can. Needless to say, you have to switch over the chucks yourself.Some machines like Ives-Way include different size chucks so you can seal a variety of different cans.

Recommended Cans for Home Use

| Common Name | Size | Capacity | |

|---|---|---|---|

| Fluid Ounces | Milliliters | ||

| 1/2 pint (1 lb), tapered | 307 x 200.25 | 8 oz | 228 ml |

| Pint, tall salmon, tapered | 301 x 408 | 16 oz | 500 ml |

| No. 1 | 211 x 400 | 11 oz, (1 cup) | 310 ml |

| No. 2 | 307 x 409 | 20 oz, (2 cup) | 600 ml |

| No. 2, 30 oz | 401 x 411 | 18 oz, (3 cup) | 850 ml |

| No. 3, quart | 404 x 414 | 33 oz, (4 cup) | 1000 ml |

Larger cans can be used for packing dry foods (peas, beans, coffee beans) that don't have to be sterilized. Commercial producers can afford to use containers of any size or shape as the recipes they use are drawn by professionally trained individuals. In addition, those plants work under the direct supervision of Food Safety and Inspection Service inspectors and every recipe is thoroughly checked for safety. A home canner should follow USDA guidelines for canning food in round cans or glass jars.

Types of Cans

Most cans are produced from tinplate. Tinplate is a thin sheet of steel, about 1/128-1/64 inch (0.2-0.4 mm) which is electrolytically coated with a very thin layer of tin on both sides. In addition, the interior of the cans is coated with a synthetic compound to prevent chemical reaction of the tinplate with the food.

The Three-Piece Cans

Three-piece steel cans are composed of the body, the bottom end and the top end (lid). The body is made of a sheet of tinplate, the sheet is made into a cylindrical shape and the ends slightly overlap. Then the ends are soldered and the soldering area is covered inside with a strip of coating for protection.

After the body of the can is formed, one end is applied by the manufacturer, called the manufacturer's end, and the other called the canner's end, is applied by the canner using can sealer.

The Two-Piece Cans

There is a limitation to how much steel can be drawn and usually the side walls are twice the diameter of the can (1:2), for example, a popular 1/2 lb. tuna fish can is a two-piece drawn can of 87 x 45 mm.

Two-piece tuna has no seam on the bottom. The can has been flipped over (bottom on top). In both types of cans, the three-piece and the two-piece cans, the top end (lid) is applied with a can sealer.

Aluminum cans offer better deep-drawing capability so the walls of two-piece cans can be longer. They are more expensive, however, they offer benefits of low weight, an excellent heat transfer conductivity and strong resistance to corrosion.

Tapered Cans

Two part tapered cans are the real space savers as they can be stacked inside one another. This lowers costs of shipping and facilitates storage. There are two tapered cans which are very popular for canning salmon: 307 x 200, 8 oz, and 301 x 408, 16 oz. The fact that there is only one seam (the lid) to worry about makes them especially attractive for home applications.

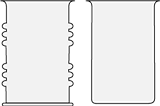

Three different diameter cans. From left to right: 307 x 200, 8 oz tapered can, 301 x 408, 16 oz, tapered can, No. 2, 307 x 409, 20 oz, straight can. Straight cans cannot be stacked.

Easy to Open Cans

Easy to open cans are extremely popular, however, they require specialized sealing equipment which is not available to a home owner.

Easy to open cans. Round cans made of steel, flat rectangular cans made of aluminium.

Fish cans are usually made from aluminum and they come in many shapes and sizes. Commercial producers need to create their own processing times, something a home owner is not able to do.

Glass Jar or a Metal Can, What's Better?

Commercial producers use metal cans not because they are pretty, they use them because they hold many advantages over glass jars. They can be processed faster, they don't break so easily and they are easier to cool resulting in a higher quality of the product.

Glass Jar

- USDA Guides offer some information and recipes. The same information can be found in other publications and on the Internet.

- Glass jars available in every large supermarket and online. Jars are standardized, almost all home canning is done in 2-part lid mason jars. The closure is not popular in Europe where most canning is done with a twist-on lid.

- Canning in glass requires little knowledge and is easy to do. A perfect seal is assured and is easily verified by visual inspection and simple testing.

- Contents are visible.

- Reusable, only lids need to be replaced.

- No specialized equipment is needed as the canning operation is performed with a pressure canner, glass jars and common kitchen tools.

- Inexpensive to purchase in low quantity.

- Safer method as there are less chances for error.

- Due to the shape of the jar, solid shaped products will break upon removal.

- Glass breaks easy.

- Glass breaks when exposed to a rapid change of temperature; after thermal treatment the jars are left to cool by themselves. Should not be handled during cooling (12 hours).

- Seal needs time to harden.

- An additional cooking takes place during initial cooling of the jars. Overcooking results in a poor texture of the food.

- Jars should be kept in dark areas otherwise there will be change in food color and the fats will go rancid.

- When cooling temperature drops to 122-150° F, 50-66° C range, thermophillic spoilage bacteria which survived the thermal treatment can start growing again.

- Commercial producers tend to process foods as fast as possible and at lowest possible temperatures. Glass jars are not suited for that.

- Glass jars are heavy. Glass does not corrode, but the screwbands do.

Metal Can

- Almost no written information for a hobbyist. A few expensive technical textbooks for people employed in the canning industry. Little information on the Internet.

- Metal cans are available only online. There are about 25 commonly used cans and choosing one may be a confusing task.

- More knowledge is required by the operator. Some basic mechanical skills are needed to change over chucks and perform simple adjustments.

- Contents are not visible.

- Used only once.

- A can sealer machine is required. A different chuck must be installed to accommodate a can of different diameter. A spacer must be installed when using a can of a different length. Some adjusting is required.

- Expensive when buying a few cans. Cheap in large quantities.

- Safe method, providing at home canners are willing to learn operating of a can sealer.

- Solid blocks such as luncheon meat or meat jelly can be removed intact.

- Strong. Packing machine can process thousands of cans per minute, something that is impractical using jars.

- Can be cooled after thermal treatment. Can be handled at any time.

- Seal is set after sealing.

- Rapid cooling after thermal treatment stops cooking.

- May be exposed to lite.

- Can be rapidly cooled to 95° F, 35° C eliminating bacterial growth and additional cooking.

- Hundreds of cans can be sealed every minute. After thermal process cooling is accomplished without a delay in the same retort.

- Cans are light. The outside surface will corrode in humid conditions.

The Verdict

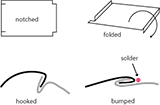

Canning in glass jars is easier to learn and jars are common. Jars cannot be rapidly cooled in home production. Canning in metal cans is a relatively simple method if one uses only one diameter cans. It requires basic skills to change chucks in order to process cans of different diameter and height. Adjusting rollers is also necessary as well as the knowledge of basic seam defects.