Meats and Sausages

Fish Sausages

Fish products and sausages are popular in countries such as the Philippines, Thailand, Malaysia, Japan, and China. The products are often made into fermented fish paste and fish sauce for general cooking. Rice is used as a filler and the source of carbohydrates for fermentation. Balao Balao (fermented rice and shrimp) and Burong Isda (fermented rice and fish) are known products.

There was research done on making fermented fish sausages, and the customer acceptance in order of preference follows below:

- Fish-pork, the highest score.

- Fish-beef.

- Fish-chicken.

The benefits of making sausages from fish:

- Cheap raw material.

- Easy to process.

- All varieties can be used, including de-boned meat.

- Healthy product.

The disadvantages of making sausages from fish:

- To improve texture, fish must be combined with pork fat, vegetable oil, other meats, and fillers like starch, soy protein concentrate, or rice.

- Fish contain little myoglobin, so treating white fish with sodium nitrite will not produce a pink color so typical in regular sausages.

- The final flavor remains fishy even when adding other meats.

It is no secret that the Japanese are masters in fish preparation. In addition to known fish such as tuna or mackerel, whale, shark and many exotic species are also served. Pufferfish or sea urchins may not appeal to Western consumers, but are elegantly prepared and served in Japan. The Japanese fish paste “kamaboko” has been eaten by the Japanese since ancient times, and fish trimmings in aspic have always been popular in Japan. in Poland. At Christmas, carp in aspic is served in Poland and fried eel in Italy.

They were studies carried out in 1925 in Japan on fish sausages, but manufacturing on a large scale never materialized. In 1938, Dr. W. Shimizu researched preparing ham from tuna meat, but the product never took off. Those early attempts were unsuccessful, most likely because they did not go well with the rice.

When World War II ended in 1945, the big fishing company, Nippon Suisan Company, researched the manufacture of fish sausage and ham from whale meat from the Antarctic Ocean and fish catches in the East China Sea. The availability of better casings, more scientific literature on the subject, and the increasing popularity of bread were the keys to success. Since 1953, the manufacture of fish sausage and ham has become a big business. Some factories produce 500,000 sausages a day at 130 g (4.5 oz) a piece, however, most sausage plants are owned by large companies that catch whales, tuna, and other fish from their ships. Fish sausage and fish ham manufacturing is such a big business that in 1962, Japan adopted quality standards for making these products. Japanese sausages are finely emulsified.

In Europe, many countries, for example, Poland, have also shown interest in utilizing less popular fish species to manufacture fish sausages. It was discovered that a sausage of good quality was made when, in addition to fish, pork, beef, eggs, and starch were included in a recipe.

There are three types of products made from fish:

- Finely comminuted sausages in small diameter casings.

- Fish hams made in casings of large diameter.

- Fish jellies.

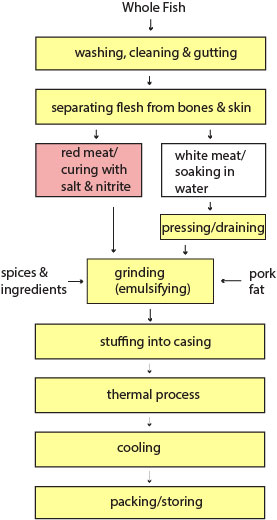

Fish sausage manufacturing follows the general steps of making emulsified cooked sausages.

Fish Sausage Manufacturing Process

A hobbyist will process a few fish, so fillets and trimmings will be relatively clean. Processes like soaking and pressing or draining may be avoided altogether.

A typical composition of a fish sausage is as follows: 67-68% water, 14-15% protein, 5-6% fat, and 8-9% starch.

A general example of a fish sausage follows below:

Meats: marlin 30% (300 g), tuna 40% (400 g), salmon 20% (200 g), pork fat 10% (100 g). Total 1000 g.

Ingredients: wheat starch 5-8% (50-80 g), sugar 1.5% (15 g), salt 3% (30 g), spices 0.5% (5 g).

Fish sausages contain about 2.5% salt in relation to the weight of the meat.

To increase shelf-life, commercial producers add chemicals, however. at home, adding common vitamin C (ascorbic acid) slows down the fat rancidity and extends the shelf-life of the sausage. Adding 0.1% of orange essential oil will provide the same effect. Remember that fat rancidity appears after a few months, even after freezing the product.

To imitate meat sausage, raw pork fat is cut into 6 mm (1/4 inch) to become a show element. They are added to the meat mixture at 7-10% of the total weight before processing. Pork back fat is better than pork belly fat, but it is hard to obtain for a hobbyist, however, he can use hard-fat pork trimmings.

Making Fish Sausages at Home

- Grind skinless and boneless pieces of fish. Different species of fish can be mixed together. Adding pork fat will make a great sausage. Those who object to using pork can add vegetable oil if needed. The flesh of the fish is very soft, and it should be partially frozen for the clean cut.

- Mix ground fish with all ingredients. Adding binders such as flour, cornstarch, bread crumbs, or cooked rice helps to develop a good texture. White of an egg is an excellent binder added to many sausages. Fish flesh is very light, so white pepper is a good choice. Fish goes well with lemon, so adding lemon salt or grated lemon zest is a good idea.

- Stuff into casings. If you use binders or fillers (flour, breadcrumbs, rice), stuff the casing loosely, because they can expand during cooking.

- Smoke (optional).

- Cook to 145º F (63º C) internal meat temperature. You can bake the sausage in a smokehouse or cook it in water at 176-185º F (80-85º C).

- Store in refrigerator.

Selecting Fish

Fresh fish should be properly chilled and used within a few days after capture. White flesh fish is preferred as sausages made from white fish have a better appearance and taste less fishy. Fish with a high fat content such as herring, mackerel, usually have a darker color and stronger fish flavor, both factors are difficult to disguise.

Frozen fish is suitable providing it was of a good quality before freezing, however, fresh fish have stronger binding properties. White flesh fish keeps better in cold storage than fatty products, because fats will go "rancid" in time. This reaction will occur even in deep cold storage, and although the product is safe to eat, its flavor deteriorates. Fatty fish should not be frozen longer than 6 months at minus 22º F (- 30º C), white fish for example cod, can be frozen at -22º F (- 30º C) for up to 9 months. Fish can be defrosted in a cooler or in running cold water.

White or red-flesh fish are suitable for making sausages. The fish is cleaned, gutted, boned, and skinned, and the flesh is removed. Some red- flesh fish such as mackerel, bonito or jack may have dark muscles and will become blackish-red after processing. These fish will benefit from being cured for 2 days with salt, sugar and sodium nitrite (cure #1) to preserve their red color. A similar procedure is used to cure meat for smoked sausages. Such treated fish are not submitted to soaking.

Red-flesh fish that is less fresh tends to remain blackish-red even when treated with sodium nitrite. Adding ascorbic acid (vitamin C) helps to correct the problem. Ascorbic acid is usually added at 0.05% (0.5 g per 1 kg of meat).

Meat with good binding properties can be mixed with fish. Fish such as marlin and lean white fish usually have good binding properties.

Like any other sausage, fish sausage needs some fat, even more, when taking into consideration that fish contain less fat than other meats. Back fat is usually diced into 5 mm (1/4”) cubes to stand out, it is a show piece. Pork back fat is preferred to belly fat. To prevent smearing it is added last during mixing.

Some people may object to using pork fat for religious reasons. Adding pork fat is not required, many fish sausages include vegetable oil at 7-10%. In Japan refined cotton oil or soy oil was added to fish sausages, but any good oil, such as olive or canola, would work well.

Red-fleshed fish meat is generally weak in elasticity after processing.

Cod (Gadus macrocephalus) is poor in fat content, and the elasticity is weak. Alaska Pollock (Theragra chalcogramma) has almost the same characteristics as cod.

Flat fish (Pleuronectidae) are generally good when fresh. With time, their binding properties decrease.

Squid (Ommastrephes sloani pacificus) can be found allover the world and is inexpensive. Squid exhibits poor binding properties, so it should only account for up to 20% of the sausage material. In its skin, the squid contains pigment agents responsible for its color, so if the skin is ground, the color of the meat will change to red. It is easier to remove the skin if the squid is briefly submerged in boiling water (212º F, 100º C).

The percentage of meat collected varies according to the species, but the average yield can be assumed to be about 40%.

Crushing and Soaking

The head, tail, fins, and entrails are removed, fish is filleted. In commercial production a "fish meat collector" is employed, which scrapes off flesh off the skin and bones. The crushed flesh is washed/soaked in water to remove fat and blood, then drained in a separator machine. A wire strainer or cheesecloth would work, too.

Often, soaked meat was placed in a cotton bag, and the bag was pressed to drain water. Draining removes some of the protein and natural juices and should be applied lightly. The chopped fish meat should never be soaked in salty water as proteins are salt soluble and will leak out significantly.

You may often come across the term "bleaching" in fish technology books, but that does not mean chlorine bleach is used. The mechanically torn meat of the fish is soaked in fresh water to remove blood, fat and any foreign material. This soaking ("bleaching") renders the meat white, removes undesirable color, taste and odor and improves the binding properties of the flesh.

Soaking removes some nutrients, meat juice and a small amount of protein. To prevent any significant loss of protein only fresh potable water must be used for soaking. Adding salt to water (using brine) will swell meat cells and release more protein. Proteins readily dissolve in salt and water will wash them away.

Grinding

If using bowl cutter (food processor) keep the temperature of the sausage mass below 59º F (15º C), otherwise emulsion may break down and ingredients might separate. Generating excessive heat will start cooking proteins, resulting in a loss of binding.

Flesh of most white fish is very delicate, so grinding it through a large plate to produce a coarse-textured sausage is futile. For home production running fish through 3 mm (1/8”) plate, refreezing the grind and then grinding it again will produce a fine paste. The better solution is to grind meat through 3 mm (1/8”) plate and then emulsify it in a food processor.

Mixing

The meat is ground, salt, spices, vegetable oil, preservatives and colorings are added. You may add salt when grinding fish, this will fasten the release of exudate which is a sticky solution of proteins, meat juice and salt. This sticky substance helps to bind all ingredients together. Starch is added to adjust the viscosity (texture) of the ground mass. Pork fat is diced or cut into strips and mixed with ground fish.

Ground fish is mixed with vegetable oil, sodium glutamate (MSG-flavor enhancer), sugar, preservatives (sorbic acid), spices and condiments, liquid smoke, and coloring materials, if used.

Lastly, starch is added to adjust the binding of the sausage paste. Starch is added as powder or in solution in the amount of 10% of the total weight of the meat. To determine the degree of binding strength, a small amount of fish paste is taken and heated, and the texture is determined by touch. If it is weak, more starch should be added; water should be added if it is too hard. If too much starch is added, the taste of the finished product becomes poor. The amount of starch added should not be more than 10% of the meat by weight. otherwise, it will affect the flavor of the sausage. Many Russian smoked sausages include about 2% of potato or wheat starch.

Ground pork skins or commercial gelatin (made from pork skin) can be added to the ground meat to strengthen binding.

Stuffing

Casings of 25-50 mm diameter can be used, protein laced water-proof casings work well as they shrink with the sausage, which prevents shriveling. If the cooled sausage is wrinkled it can be inserted for 1 minute into boiling water, and the wrinkles should go away. Waterproof casings are recommended. Make sure the sausage mass is not watery, as the moisture will not be able to evaporate. If the sausage is to be smoked use natural, cellulose or fibrous casings, which allow the smoke and moisture to go through.

Cooking

In a commercial plant the sausages are processed in a boiling water tank, generally heated with steam. In large factories, a continuous cooker is used. The apparatus consists of two boiling tanks, a cooling tank, and a short-time boiling tank in one connected unit. In the first boiling tank, kept at 167º F (75º C) the pieces of fish sausage, on a conveyor, are immersed in water for 10 minutes; then they are carried into the second boiling tank, temperature 185º F (85º C) where they are immersed for 60 minutes.

The fish sausages are processed 60 minutes at 176-185º F (80-85º C) in continuous cookers and then cooled in a continuous cooler. When the sausages become wrinkled. the wrinkles are removed by soaking the cooled sausages in boiling water for one miinute. The finished fish sausages are packaged in cellophane.

Cooling

After cooking the sausages are cooled in a cooling water tank, at 50º F (10º C) where they are cooled rapidly with running water for 10 minutes. Finally, they are immersed in boiling water for 1 minute for removal of c wrinkles caused by the cooling.

Drying

Moisture on the surface of the processed sausage is removed by passage through a dryer (hot-air blowing).

Salt, Spices and Ingredients

The amount of salt is 2.5% of the total amount of the crushed mixed meat.

Starch is added to improve binding of ingredients together. Many Russian sausages contain about 2% potato flour or starch. Starch binds meat even better than flour; both, wheat and potato starch can be used. Sausage makers claim that potato starch is better as its gel is more elastic. Adding more than 10% starch may affect the flavor of the product.

- Commonly added spices are pepper. nutmeg, sage, cinnamon, cardamom, cloves, onion, garlic and mustard.

- Liquid smoke can be added for smoky flavor.

- Phosphates applied at 0.2-0.5% effectively bind water.

- Soy protein at 2-5% binds water and improves texture.

- TVP, textured vegetable protein binds water and is a great filler that extends the value of the sausage.

- Carragenaan (sea weed) improves the cohesion and sliceability of any meat product. It is added from 0.01% (1 g per 1 kg of meat) to 1.0% (10 g per 1 kg of meat).

- Sugar at <5% improves the flavor.

Antioxidant agents such as ascorbic acid delay somewhat the usual changes in taste and color of fish sausage. Ascorbic acid speeds up the development of pink color when sodium nitrite is used.

Fish Sausages and Safety

Fish safety considerations are covered in our Fish Section.

Fish sausage recipes are listed in our Sausage Recipes Index.