Meats and Sausages

Concrete Block Smoker

An excellent smoker can be built in no time by using standard 8”x 8” x 16” concrete blocks. A firm support base is required, and square patio stones of 12”, 16”, or 18” that are available at garden centers can be successfully used. Even bigger prefabricated concrete slabs 30” x 30” that are used to support outside air-conditioning heat pumps are commonly available in warehouses with building supplies. They may make an installation look prettier but are not necessary, a bare ground is fine. Just grade it well so it is leveled.

The construction does not require mortar, just arranging blocks in the manner that will be most practical. A separate fire pit built from blocks is easily built and attached to the smoker. This way, the entire smoking chamber can be utilized for smoking meats and the whole process will be easy to control and enjoyable. Nothing stops you from using mortar and making it a permanent structure but a strong suggestion will be to try it out a few times and make some observations that may help you with any future decisions regarding building a permanent smoker. It is also worth noting that once in a while a block may crack, especially, the ones that are in direct contact with fire. If the mortar is not used, the block can be replaced within minutes; otherwise, it becomes a project. In addition, relocating the smoker that was built with mortar-connected blocks is difficult due to its weight.

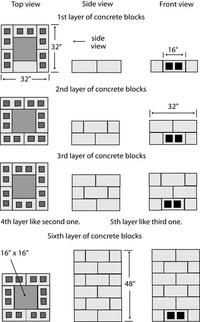

This is a totally flexible design, imagine a child who is building a tiny house with little building blocks. This is how this smoker is built; the only difference is that concrete blocks are bigger: 8’’ x 8” x 16”. All needed materials are available from a building supply store and the final cost will be incredibly low.

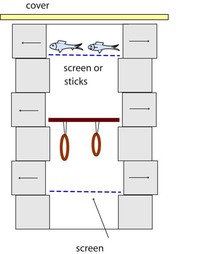

Smokesticks Support

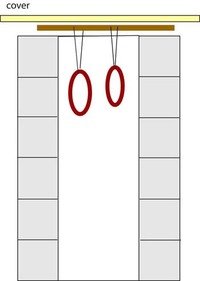

The easiest and fastest way to support the smokesticks (not the screens) is to place them directly on the top of the smoker. The sticks should be 1” in diameter as they act as spacers now, separating the top of the smoker from the cardboard or wooden cover that rests on it. This creates an opening for the smoke to exit from the smoker. This also limits us to two smoke sticks (one level). An old potato burlap sack has been used for that purpose for hundreds of years. Of course, a flattened piece of cardboard or a piece of plywood can be used as well.

Construction Details

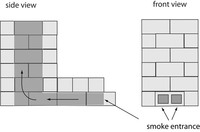

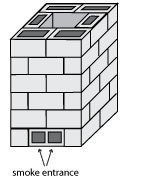

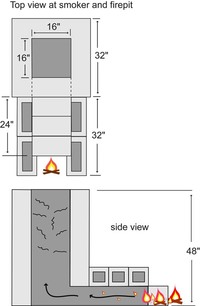

The block laying style repeats itself, uneven layers 1, 3, 5 have one pattern, even layers 2, 4, 6 have another one. There are 5 blocks in #1 level, all others require 6 blocks. In a six-floor configuration, a total of 36 blocks are used for the smoker and 7 blocks for the fire pit. Neither masonry bricks, mortar, half blocks, or any tools are needed. As the fire pit is on the same plane as the smoker, in order to achieve enough draft, the smoker has six floors and is 48" high, which makes it a comfortable height to work with. It will also work if the height is limited to 5 block levels (40") and if more draft is needed, an extra floor can be added in a matter of minutes. The blocks can be spaced so that every other row can have two blocks projecting inward from the wall on each side of the smoker. This arrangement creates support for the smokesticks, screens, or racks.

Fire Pit

There are only 7 blocks needed to construct the fire pit which is freely attached to the front wall. Any little smoke coming from the connection is negligible as long as there is smoke coming out of the chamber. A wet towel can be placed over the connection where the fire pit and smoker come together. A fire pit may be attached to the smoker with a mortar, but not necessary providing the ground is level. As the concrete block is not designed to withstand high temperatures, it is to be expected that once in a while one of the fire pit concrete blocks might crack. Obviously, the most practical solution is to replace it with a different one and go on happily smoking like before.

A long-stem thermometer can be inserted between blocks or through the top cover. The temperature control and amount of heat generated are obtained by moving burning wood closer or away from the entrance to the smoker. This is a fully functional and easy-to-operate smoker capable of producing smoked meats of the highest quality, so it should not be judged by its looks. Its useful inside space is only 0.7 cubic feet (0.18 cubic meters), smaller than that of a typical 55-gallon metal drum. Resting smokesticks on two separate levels creates enough capacity to smoke about 22 lbs (10 kg) of meats.

Concrete Block Smokehouse-Construction Images

Fire pit can be made longer. A sheet of metal may be placed on top of a fire pit instead of concrete blocks.

About Safety

Keep in mind that there is enough draft to start a fire when burning wood. The following pictures demonstrate how the fire started when leaves, branches, and scraps of wood were disposed of by burning them in the fire pit. The burlap bag was left on and caught fire. A good precaution is to have a garden water hose lying nearby. It may save you a fine when a fire truck comes by because your unfriendly neighbor reported dense smoke in the neighborhood.

The above information is reprinted with permission from Meat Smoking and Smokehouse Design.