Meats and Sausages

Sauerkraut Fermentation

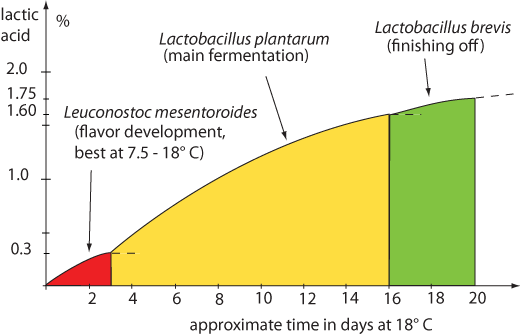

Sauerkraut fermentation requires almost no work on the part of the operator. Cabbage contains enough lactic acid bacteria in order to ferment and produce sauerkraut with salt alone. In order to obtain product of the highest quality all those bacteria strains must ferment in a certain sequence. This happens naturally as long as sauerkraut is fermented around 65° F (18° C).

- Leuconostoc mesenteroides - they are the smallest and start the fermentation first producing around 0.25 to 0.3% lactic acid. They are heterofermenters, this means that they produce different compounds such as lactic acid, acetic acid (vinegar), ethyl alcohol, carbon dioxide (soda gas) and mannitol. The last one is a bitter flavored compound which is metabolized later by Lactobacillus plantarum. All those acids, in combination with alcohol from aromatic esters, contribute to the characteristic flavor of the high quality sauerkraut. If the temperature is higher than 72° F (22° C) they might not grow and that would be detrimental to the flavor of sauerkraut. In about 2 days Leuconostoc mesenteroides will produce 0.3% lactic acid and this increased acidity will restrict its growth. Nevertheless, the enzymes it produced will continue to develop flavor.

- Lactobacillus plantarum - this strain takes over the production of lactic acid from Leuconostoc mesenteroides and continues fermenting until an acidity level of 1.5 to 2% is achieved. L. plantarum will ferment at temperatures higher than 72° F (22° C) and it can grow at higher acidity levels. It will ferment at lower temperatures as well, albeit at much slower rate. Lactobacillus plantarum is the most popular lactic acid bacteria strain and it ferments sauerkraut, pickles, cheese and even meat. This bacteria is a homofermenter what means that it produces one compound only. It consumes sugar and produces lactic acid which imparts acidic taste to fermented food. At the end of this stage sauerkraut has an acceptable quality and can be served or canned. If there is enough sugar left, the fermentation will continue until all sugar supply is exhausted.

- Lactobacillus pentoaceticus ( L.brevis) - continue fermenting until an acidity level of 2.5 - 3% is obtained. As there is no more sugar left in the cabbage the fermentation comes to the end.

Sauerkraut fermentation.

Any change to the above cycles of lactic acid production will alter the taste and quality of sauerkraut. As long as the proper amount of salt is added and the recommended temperatures are observed, the three bacteria strains will ferment cabbage in the proper sequence.

Effect of Fermentation Temperature

The best quality sauerkraut is produced at 65-72° F (18-22° C) temperatures. Temperatures 45.5° F (7.5° C) to 65° F (18° C) favor the growth and metabolism of L.mesenteroides. Temperatures higher than 72° F (22° C) favor the growth of Lactobacillus species. Generally, lower temperatures produce higher quality sauerkraut, although at 45.5° F (7.5° C) bacteria are growing so slow that the cabbage might need 6 months to complete fermentation. Higher temperatures produce sauerkraut in 7-10 days but of the lesser quality. This creates such a fast fermentation that some types of lactic acid bacteria don't grow at all and less reaction take place inside what results in a less complex flavor.

- Below 45.5° F (7.5° C) fermentation time is up to 6 months.

- At 65° F (18° C) fermentation time is 20 days.

- At 90-96° F (32-36° C) fermentation time is 10 days.

Bacteria Control

Sauerkraut is made by lactic acid bacteria that break sugar into lactic acid, carbon dioxide (CO2, soda gas) and a little amount of alcohol. Because cabbage contains water, sugar and many nutrients it is a perfect media for all types of bacteria to grow, some of them we try to avoid. Heat treatment will surely kill undesirable bacteria, but it also will kill lactic acid bacteria that we need, so this method does not apply here.

pH acidity of fresh cabbage is at around pH 7.0 which is at neutral point of acidity scale. This makes cabbage an ideal food for microorganisms as it contains water, sugar, proteins, minerals and all nutrients. We control bacterial growth using the following steps:

- Washing.

- Applying salt.

- Elimination of oxygen.

Washing. Cabbage is in a direct contact with soil which is loaded with all types of microorganisms. Most microorganisms are present on outside green leaves which are usually discarded. One gram of fresh cabbage may contain 250,000 bacteria and this number may grow to 1,000,000 during storage. So, the first step is to wash the cabbage well as this action removes plenty of microorganisms. If ingredients such as apples or carrots will be added, thy must be thoroughly washed as well.

Salt. Salt is needed for two reasons:

- To remove the cabbage juice and nutrients from each cell and make it available as food to lactic acid bacteria. Bacteria will not eat dry cabbage leaves, however, they will absorb filled with nutrients juice. Bacteria are like sponge, they don’t pick up the dry matter but will suck up anything wet.

- To keep other bacteria away. A moderate amount of salt does not bother sauerkraut bacteria (lactic acid), however, other bacteria types find such conditions intolerable.

As lactic acid bacteria start to produce slowly lactic acid, this becomes even worse for other bacteria types, as generally bacteria hate acid. Of course lactic acid bacteria are not bothered by moderate amounts of acid at all. This combination of salt and increasing amount of acid inhibits growth of other bacteria and makes sauerkraut more stable as the fermentation advances

To make high quality sauerkraut salt is applied at 2 – 2.5% in relation to the weight of the sliced cabbage. Decreasing salt levels will create quality problems, going below 1.5% will rot the cabbage. Spoilage bacteria will survive such a low salt level and will take over the process and will spoil the product.

Absence of Oxygen. When container as packed with cabbage all microorganisms start to compete for food. Salt inhibits some of them, but many others need oxygen to survive, for example molds. Eliminating oxygen is accomplished by a few methods:

- Packing container hard with shredded cabbage.

- Slicing cabbage thinner, this allows to pack more cabbage and disperse more air.

- Keeping cabbage submerged in brine (using weights).

- Using water channel fermented crocks or air lock glass jars.

Eliminating oxygen preserves vitamin C from oxidizing and losing its strength.

Fermented sauerkraut exhibits pH at around 3.5 and will keep in cool conditions for a very long time, as long as this pH level is maintained.

Tips

Cabbage should contain up to 3.5% sugar. The sweeter raw cabbage is the better sauerkraut will be obtained.

Adding less than 2% salt might produce soft or even slimy sauerkraut. Adding less than 1% will produce sauerkraut that would be soft and unacceptable commercially. Adding more than 3.5% salt might inhibit growth of lactic acid bacteria.

The more lactic acid is produced the more acidic sauerkraut becomes. There is a limit how much lactic acid can be produced. Once the sugar supply is exhausted, lactic acid bacteria stop growing. White scum on the surface of the sauerkraut is due to yeasts and should be removed daily. There is no reason to discard the sauerkraut.

It is possible to use the brine from the previous sauerkraut fermentation as a starter culture for a new production. This is a common method used in production of bread or even salami (back slopping), where a part of fermented product is saved for a new production. In theory at least, it should produce a new batch with the same characteristics as the old one.

If more sugar were added the fermentation will continue longer and more lactic acid will be produced. That would result in increased acidity and very sour cabbage which is not desirable. Eventually the acidity level will be so high that lactic acid bacteria will not survive.

During fermentation glucose (sugar) is converted to about 50% lactic acid, 25% acetic acid and ethyl alcohol, and 25% carbon dioxide.

Keep the fermentation temperature below 80° F (27° C). For best quality sauerktaut maintain fermentation temperature at around 65° F (18° C).

Bubbles are the sign of ongoing fermentation. In a glass jar they can be seen raising to the top.