Meats and Sausages

Smoking Fish

Salting and smoking fish was practiced for centuries. Man discovered that smoking was a very effective tool in preserving fish. Heavy salting and long periods of cold smoking preserved fish well enough so they could be kept for months without spoiling. From the Middle Ages until the 1900s, fish were heavily cured with salt and cold smoked for 3 weeks or more. With the development of railways in 1840, it became possible to distribute fresh fish to wider areas, and the fishing industry started to grow rapidly. Due to the availability of fresh fish, the taste for heavily salted, smoked, and dried fish declined, and people came to prefer less salty foods. Fish are hot smoked today for a pleasant taste, which is achieved with less salt and shorter smoking times. Refrigeration takes care of preserving foods.

Besides enhancing the taste and look, smoking increases the product’s shelf life. It helps preserve the meat by slowing down the spoilage of fat and growth of bacteria. The advantages of smoking fish are numerous:

- Slows down the growth of bacteria.

- Prevents fats from developing a rancid taste.

- Extends the shelf life of the product.

- Develops a new taste and flavor.

- Changes the color of smoked products to make them shine and look better.

The main reason to smoke fish at home today is to produce a product that cannot be obtained in a typical store. One can order traditionally made products on the Internet, but they will be very expensive.

What is Smoking ?

Smoking meat is exactly what the name implies, flavoring meat with smoke. Using any kind of improvised device will do the job as long as smoke contacts the meat surface. The strength of the flavor depends mainly on the time and density of the smoke. Smoke is a mixture of air and gases created during wood combustion. What we see is a stream of gases such as nitrogen, carbon dioxide, carbon monoxide, water vapor, and sulphur dioxide that carry unburned particles such as tar, resins, soot, and air borne ash. The actual composition of the smoke depends on the type of wood, its moisture content, combustion temperature, and the amount of available air. It is estimated that smoke consists of about 10,000 individual components, and a few hundred of these are responsible for the development of a smoky flavor.

The air draft, which might be considered the smokehouse sucking power, sucks in the fresh air from the ouside and with smoke and combustion gases creates a turbulance inside the smoking chamber. This turbulance attracts solid unburned particles such as soot, ash, and others. On its way out, this stream collides with hanging meats and with the walls of the chamber. A stronger air draft and higher temperature increase the energy of the smoke, which results in more intense smoking. The amount of moisture on the surface of a product plays a role in color formation, given that wet meat attracts unburnt particles better. This also results in a much darker color as particles such as tar and soot easily stick to the surface.

Smoking meat consists of the following steps:

- Curing with salt.

- Applying smoke.

- Cooking.

Meat can be smoked yet still be raw inside. It must be cooked to the recommended temperature before it is safe to consume. This cooking process may be accomplished in a smokehouse, an oven, or in hot water. Some products are smoked at low temperatures and never cooked. Their safety depends on heavy salting and the removal of moisture. Those products are cold smoked.

There are two methods of smoking:

- Cold smoking, at temperatures below 85° F (30° C).

- Hot smoking, at temperatures from 120-220° F (50-104° C).

Many people assume that each method uses a rigidly implemented range of temperatures and processing times, but this is not true, especially for the hot smoking method. It is worth noting that sausages are rarely smoked above 160° F (72° C). However, after smoking is done, they may be baked (a thin smoke allowed) in a smokehouse at 185°-190° F (85°-88° C).

| Smoking Methods: | Cold | Hot |

| Time required | days, weeks | hours |

| Temperature | below 85° F (30° C) | 120-220° F (50-104° C) |

| Salt | yes, a large amount | little, just for flavor |

| Method of preserving (killing bacteria) | salt plus drying to remove moisture | high temperature to kill bacteria |

| Product shelf life | long | short |

| Texture | firm | soft |

| Taste | good | very good |

| Curing | prolonged heavy salting | of little significance |

| Cooking | none | yes |

| Smoke penetration | in all areas of meat | surface areas only |

After smoking, the fish will weigh less due to the loss of moisture. The yield of the hot smoked fish is about 70-75% in relation to its original weight. The yield of the cold smoked fish is about 55-60% in relation to its original weight. The majority of fish is hot smoked today since preserving them is accomplished in a refrigerator. Canning takes care of fish products that need to be stored for a long time without refrigeration.

Cold Smoking Fish

Cold smoking is an old technique that was practiced not because it produced great flavor but because it helped to preserve meats. There was no refrigeration, but meats had to be preserved. Cold smoking is drying meat with smoke. Its purpose is the elimination of moisture so that bacteria would not grow. This technique was developed in North European countries where the climate was harsh and the winters severe. When meats were cold smoked for 2-3 weeks, yes, the meat became preserved due to the loss of moisture, but it was drying that made the meat safe. If the same meat was dried at 54° F (12° C) without smoke, it would be preserved all the same. Fish is smoked below 80° F (26° C) from 1-5 days. Temperatures above 80° F (26° C) will start cooking the fish. Cold smoked fish is considered raw meat as it is never exposed to high temperatures; there is no cooking. That is why it has to be heavily salted or brined at 16% salt (65 degrees brine or higher) to provide safety to the consumer. The best range of humidity for cold smoking at 80-85° F is 60-70%.

The longer the smoking period, the more moisture is removed, the drier the product becomes, and, of course, it develops a longer shelf life. This method of smoking can last up to a few weeks, and the fish will have excellent keeping qualities. After prolonged cold smoking, the fish has lost enough moisture to be considered safe without additional cooking. Fish that were cold smoked hold well together and can be very finely sliced, which cannot be done if the fish were hot smoked. Traditionally, cold smoked products contained up to 15% salt and were smoked and dried for a long time.

Cold smoking is not a continuous process; it is stopped a few times to allow fresh air into the smoker. Because of the time and costs involved, cold smoking is rarely used today. In addition, cold smoked products are heavily salted, which makes them less appealing to the health-conscious consumer of today. The majority of hobbyists think of cold smoking as some mysterious preservation technique that will produce a unique and superb quality product. Cold smoking is not a preservation method; it will not preserve meat unless proper conditions are established for the meat to dry.

Cold smoking at its best. Waldemar Kozik is making meat products of the highest quality in the Catskill Mountains of New York.

The pigs were traditionally slaughtered for Christmas, and the meat had to last until the summer. Noble cuts were cooked or salted; the trimmings were used for sausages. They needed to be dried to last through the winter. That was not easy with freezing temperatures outside. The only way to heat up storage facilities was to burn the wood, and that produced the smoke. There were two choices for protecting meats from the heat:

- Hanging meats 5 feet above a small smoldering fire.

- Burning wood in a firebox that was located outside.

The firebox was connected with the smokehouse by an underground channel that would supply heat and smoke at the same time. A large smokehouse was also a storage facility; after meat was smoked, it was hung in a different area where it continued to receive some smoke, although on a much smaller scale. This prevented molds from growing, as molds need oxygen to live.

It had been established that meats dried best when the temperatures were somewhere between 50-60° F (10-15° C), and although the temperature of the smoke leaving the firebox was higher, it would be just right by the time it made contact with meat. Whole logs of wood were burnt, and wood shavings and sawdust were used to control the fire. The fire was allowed to die out as people went to sleep. The meats hung through the night, and the fire was re-started again. So, when you see an old recipe saying that ham or sausage was smoked for 2 weeks, well, it really was not, as it probably received continuous smoke for about 1/2 of the time. Those meats were not cooked; they were dried and could be considered fermented products. There is little difference between Italian salami, Hungarian salami, or Polish Cold Smoked Sausage.

Italian salami was dried without smoke, and Hungarian salami and Polish sausage were dried with cold smoke. Italians and Spaniards were blessed with a climate that provided cool prevailing winds at right temperatures. There was no need to burn wood to warm up the drying chambers. As a result, the products did not acquire a smoky flavor. People in the Mediterranean basin are not particularly fond of smoked products, but people in Germany, Poland, Russia, and Lithuania love them. The majority of all processed meat products in Northern Europe are of the smoked variety.

All Polish, German, Russian, or Lithuanian technology books about smoking agree that cold smoke should be applied below 72° F (22° C). Occasionally, a book calls for 77° F (25° C). Old German books specify the temperature of cold smoke as 64° F (18° C) or lower. Any recipe that calls for cold smoke higher than 85° F (30° C) makes little sense, as above this temperature, proteins coagulate and the texture of the meat changes. The meat gets cooked. The surface area will harden, preventing moisture removal, and the product will rot inside. This hardened ring will also inhibit smoke penetration.

To summarize, the purpose of cold smoking was to dry meats. The product was drying out, and the smoke happened to be there. Preservation was on people’s minds and not creating cold smoked flavor.

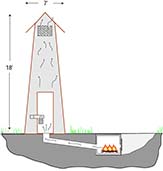

Smokehouse for Cold Smoking

There is less expectation from a smoker which is dedicated to cold smoking only. A cold smoking unit has no need for high temperatures, so its design is simple. The outside conditions are a deciding factor whether cold smoke can be produced. In many areas, you cannot produce cold smoke in the summer unless steps are taken to cool it. You can produce cold smoke in tropical regions in the winter months at night time, but keep in mind that the humidity will be high. Any enclosure, such as a carton box, drum barrel, or wooden box, is suitable as long as the flames do not make direct contact with the fish. /p>

Early Commercial Fish Smokehouses

Meats and sausages were smoked by butchers in small smokehouses. Small smokehouses could hardly cope with the demand of the fishing industry. The first industrial-type smokehouses appeared in England and were specifically dedicated to smoking fish. Since electricity was not invented yet, the units were designed for cold smoking. Often, entire buildings were converted into smokehouses, where the basement served as the smoke generator and the fish were placed on the first, 2nd, or 3rd level. They can be seen here.

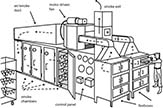

As technology evolved, the brick and cinder block smokehouses were replaced with insulated stainless steel units. Electrical blowers and metal ducts supplied smoke, and the rotating dampers distributed heat precisely to all areas of the smokehouse. This second generation of smokehouses was called the batch oven type. In batch smokehouses, the meat was hung on smokesticks or placed on stationary racks for the entire smoking process. Then came smokehouses, where meat traveled through the various zones (smoking, heating, chilling) within the smokehouse. The product was packaged and stored or shipped.

The technique of hot smoking fish probably originated in Germany and Holland, where mainly fatty fish were processed in small brick kilns capable of reaching a high temperature and retaining the heat. Hardwood logs damped with wet sawdust produced a lot of heat, humidity, and intense smoke. This heat and humidity gave a cooked product that golden brown color and a silky sheen on the skin.

Torry Kiln Smokehouse

Until 1939, most smokehouses were always built the same. They depended on a natural draft movement to control the flow of heat and smoke without any means of humidity control. Given that the majority of these smokehouses smoked meats for preservation purposes, the temperature was of little concern as long as the smoke was cold. Torry Kiln was the first design that employed an independent means of draft and temperature control. It was a mechanical kiln that used blowers to push smoke and electrical or steam heaters to generate heat. The Torry Kiln design allowed for precise control of smoking parameters such as air temperature, its speed, and humidity. As a result, the finished product was always of consistently high quality. The Torry Kiln design incorporated a motor-driven fan, electric heaters, temperature sensors, air diffusers, and even a photoelectric eye for smoke density control. To read more about Torry Kiln go to Torry Kiln.

Torry Kiln Fish Smoking Times

Torry Kiln is a very efficient smokehouse where smoke parameters, humidity and air velocity are precisely controlled. For a simple home made smokehouse, smoking times should be increased.

| Fish Type | Smoking time in hours, below 85º F (30º C) | Soaking time in 80º brine |

| *Finnan haddocks <1 lb | 3 | 7 min |

| *Finnan haddocks 1-1-1/4 lb |

4 | 10 min |

| *Finnan haddocks > 1-1-1/4 lb |

6 | 15 min |

| *Glasgow pales | 2-2.5 | 4-5 min |

| Cod and haddock fillets | 2-5 | 4-10 min |

| *Golden cutlets | 2-3 | 4 min |

| **Kippers | 4 | 15 min |

| **Kipper fillets | 2.5-3 | 3-4 min |

| **Bloaters | 4 | dry salt, 8 hrs |

| Salmon fillet 1.5-2 lb | 12 | dry salt, 12 hrs |

| Salmon fillet 3-4 lb | 12 | dry salt, 16-20 hrs |

| Salmon fillet 5 lb | 12 | dry salt, 24 hrs |

| Cod roe | 6-8 hrs, 90-100º F | dry salt, 6-8 hrs |

| **Buckling | 1st hr, 80-90º F, 2nd hr, 110-120º F, 3rd hr, 160-170º F | 60 min |

| Smokies 0.5-0.75 lb | 1st hr, 80-90º F, 2nd hr, 110-120º F, 3rd hr, 160-170º F | 30-45 min |

| Trout | 2.5 hrs, 90-180º F | 60 min |

| Sprats | 1 | 15 min |

| *Seelachs fillets, thin | 30 min | dry salt, 12 hrs |

| *Seelachs fillets, medium | 30 min | dry salt, 16-20 hrs |

| *Seelachs fillets, thick | 45 min | dry salt, 24 hrs |

| Smoked oysters | 30 min at 180º F | 5 min in 50º brine |

* cod family, Seelachs include Saithe and Coaley.

** herring family

Hot Smoking Fish

During hot smoking, the product is smoked and cooked at the same time, making it ready to eat. For hot smoking, the smokehouse temperature may vary from 120-284° F (50-140° C) or even higher. At those upper temperatures, we bake fish. Hot smoking contributes to the safety of the product, however, this beneficial effect is confined to the surface of the fish. The safety is achieved by killing bacteria with heat. The 2-3% salt in present-day smoked products is too low to prevent spoilage, and that is why they have to be kept in the refrigerator. Hot smoking involves the following steps:

- Curing with salt

- Drying

- Smoking/Cooking

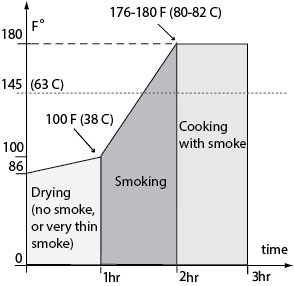

Hot smoking is basically performed in three stages:

- A preliminary drying period at 86° F (30° C) during which the skin is hardened to prevent breakage. The air dampers are fully open for maximum air flow and moisture removal. This period lasts from 30-60 minutes.

- A heavy smoke is applied for about 30-45 minutes with the exit smoke damper left at ¼ open position. The temperature is gradually raised to 122° F (50° C).

- The temperature is raised to 176-180° F (80-82° C), and the fish is cooked to 145° F (63° C) internal temperature for a minimum of 30 minutes. Depending on the size of the fish, this stage may last from 30–60 minutes. A light smoke may be maintained. When the temperature is raised to 176-180° F (80-82°C), the fish is cooked. Fish is considered done when cooked to 145° F (63° C) internal temperature and held at this temperature for 30 minutes.

Typical fish fillets are smoked for 1 to 5 hours, depending on the size. When smoking is finished, the fish should be first air-cooled to the ambient temperature and then kept under refrigeration to prevent the growth of microorganisms. This cooling process should be accomplished within 12 hours. The moisture content of most smoked fish averages 60-75%, which is still much too high to inhibit the growth of bacteria, so the fish has to be kept under refrigeration. Fish is cooked when its meat flakes out easily when pressed with a knife or a fork. Different sources quote different temperatures and processing times, so use your own judgment.

A typical hot smoking of the fish.

The parameter that overrides all others is the safety of the product; the internal meat temperature as recommended by our government - the fish should be cooked to 145° F (63° C) and held at this temperature for 30 minutes. Once this temperature is reached, the product is safe to consume. It makes little difference whether the fish was processed at 70, 80° C, or 100° C, as long as the 145° F requirement was met. It will turn out to be fine at all three settings;, of course, the length of processing time will be different at each temperature.

The control of brining, drying, and smoking factors is left to the discretion of the person conducting those operations. In time, you will be able to use your own judgment, and the cause of action taken will be based on factors such as the type and the fattiness of the fish, its size, and how it was prepared (whole fish, split fish, or fillets). Those factors will influence processing parameters, however, the safe cooking temperature must be reached, and the fish is either cooked or not.

Cold smoked products are an exception, as their safety does not depend on heat but on the amount of lost moisture. In most home made smokers the internal meat temperature lags the smokehouse temperature by about 25-30 degrees. For example, to reach 180° F (82° C) internal fish temperature, the smokehouse must be capable of maintaining from 200° F (104° C) to 212° F (100° C). In winter, it may be a difficult task to accomplish if using a metal barrel smoker unless it is heavily insulated. If the smoker can not reach the required temperature, the fish can be smoked long enough to acquire the color and the flavor, but the cooking step should be completed in an oven.

Hot Smoking Fish In Russia and Poland

Both countries are known for producing excellent smoked hams and sausages. During the communist era, Poland has been building not only fish trawlers but the mother factory ships that were receiving fish catches from fishing trawlers. The factory ship would collect fish from fishing trawlers and process and can fish at sea. Russia produces a large assortment of seafood products and accounts for 95% of the production of caviar. To make it short, both countries were established players in the fish processing field. After consulting many Polish, Russian, and German technology books, we discovered that those countries smoke fish at high temperatures.

| Country | Fish Smoking Method | Temperature |

| England | Cold | 60-86° F (15-30° C) |

| Hot | up to 212° F (100° C) | |

| Germany | Hot | 212-284° F (100-140° C) |

| Poland | Cold | 68-82° F (20-28° C) |

| Hot | 158-284° F (70-140° C) | |

| Russia | Cold | 68-90° F (20-32° C) |

| Hot | 176-248° F (80-120°) | |

| Data from 1960 | ||

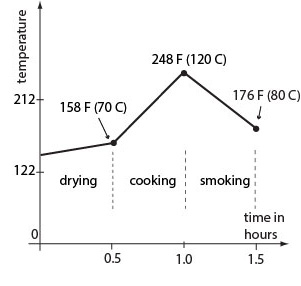

The smoking process consists of three steps:

- Drying

- Cooking

- Smoking

Drying. The main purpose of drying is to remove moisture and harden the skin and head. As a result, the skin does not crack during the second smoking stage, which takes place at a higher temperature. The head also hardens and will not break away later. Keep in mind that a large fish is heavy, but the flesh is quite delicate. The smokehouse is preheated with wood chunks; then, the fish is placed inside. All dampers are open to facilitate the removal of moisture. The drying takes place at 140-176° F (60-80° C) and continues for 30-60 minutes.

Cooking. More wood chips are added, and the temperature is gradually raised. The fish is baked at 230-284° (110-140 C). Wood chips are burning with a small flame. The exit damper is gradually decreased, sawdust is added on hot coals, and thicker smoke is produced.

Note: fat fish should be cooked at temperatures not exceeding 212° F (100° C); otherwise, the fat will start dripping down.

Smoking. The smoking continues, but the temperature is allowed to slowly drop below 230° F (110° C).

Russian method of hot smoking fish.

Hot Smoking Fish at Home

Uniformity of smoking and drying is difficult to achieve in traditional wood fired smokers when products are placed on different levels. Fish on the bottom sticks will be dried, while the fish higher up the smoker, surrounded by wet, steamy smoke that has already passed the fish below, will become wetter. Wet fish will attract more soot and unburned particles, and its color is poorer. More heat is present in the back of the smoker than in the front. To compensate for these irregularities, the smoked products were rotated. The back of the fish or the skin of the fillet should face the back of the smoker. This allows for the better judgment of the fish color and protects the flesh from higher temperatures that are normally found in the back of the smoker.

When using a few levels of smokesticks insert the upper row first, then after 5-10 minutes, the lower one, and then the lowest one. If all three levels were placed in a smokehouse at the same time, the uppermost row would get the least of the available heat during drying. On the other hand, it will get the most moisture which it will gather from the smokesticks below. Large, heavy fish must be heat-dried in a smokehouse before the smoke is applied. This hardens the fish and prevents them from falling down into the fire. A security screen should be positioned above the fire to catch any fish that might break free. Keep in mind that fat fish, when hot smoked, will drip some oil. If this oil drips into hot embers, the flames will shoot up and might even reach the fish above. Place an oil-collecting aluminum foil pan between the fish and the smoking wood. It may be placed on a security screen.

A big advantage that a hobbyist has over a commercial producer is that he can experiment at will. He can introduce into the sawdust fresh herbs such as sage, rosemary, dill, crushed juniper berries, bay leaf, or celery leaves. A typical process for hot smoking bigger fish (carp, eel, red fish):

- 1st hour- gradually increase the temperature to 158° F (70° C) to dry the fish.

- 2nd hour - smoke fish at 158-176° F (70-80° C).

- 3rd hour - cook/smoke fish at 212-230° F (100-110° C) for about 30 minutes. Switch off the heat, add a few herbs to wood chips, and smoke for another 15 minutes.

Smoking fish at higher temperatures drastically shortens the process. The fish can be smoked/baked in 30 minutes at 300-350° F (150-180° C), which can be considered barbecuing. Such a short time, however, will produce a little smoky flavor. The best course of action is to apply smoke for 60 minutes at 100-140° F (38-60° C) and then cook the fish at high temperatures. This can be easily accomplished even in a regular barbecue grill by filling a holed metal box with wood chips/sawdust and then placing it on hot charcoal briquettes. Once the chips ignite, they will keep on producing smoke. The simplest arrangement is to wrap up wooden chips with aluminium foil and make some holes in it with a nail. Ready-to-use cast iron or stainless steel cigar box-sized containers are sold in the barbecue section of a large store. Do not wet your chips, as this will create a delay in producing smoke as moisture will have to evaporate first.

Smokehouse for Hot Smoking

The most difficult part of hot smoking is maintaining the temperature while burning wood chips. Burning whole logs is not easy and requires continuous attention. Using thermostat-controlled electric heating elements simplifies the process, but only for small units. A larger unit, like the 20 cubic-foot smoker below, needs powerful heating elements for hot smoking. Look at the modified warming oven that was converted into an industrial quality smokehouse by Gary Zarebski of Wisconsin.

Propane Heated Smokehouse

If you live in a cold climate and need a smokehouse that will work well, consider using propane gas. The design is very simple: a hole is drilled through the side of a smoking chamber, and a gas delivery pipe is inserted. The inside of the pipe holds the burner, and the outside section is connected to a regulator and the tank.

Using propane gas offers an instant supply of a huge amount of heat and fine control, is inexpensive, portable, and can be used in remote areas.

Smoke Generator

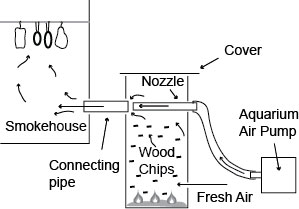

Smoke can be generated by burning wood in a fire pit or by heating a metal pan filled with small wood chips or sawdust. Once they get hot enough, they will produce smoke for 20-30 minutes. An interesting approach is to connect a little smoke generator that works with an aquarium tank air pump. Such a smoke generator can be attached to any enclosure, including a corrugated paper box.

Air pump smoke generator.

The pump delivers pressurized air into the smoking chamber. A vacuum forms in a little gap between the nozzle and the smokehouse connecting pipe. This vacuum pulls in smoke from burning wood chips, and the rushing air delivers this smoke into the smokehouse. The smoke output is determined by turning the dial on the air pump that adjusts the speed of the air pump.

Be aware that propane gas burners provide a lot of heat. The 40,000 BTU burner pictured above is considered a small burner, but it is still the overkill for any smoker smaller than 20 cubic feet capacity. In warm weather, it may be difficult to maintain temperatures of 140° F (60° C) or lower. For smaller smokers, an electric heating element might be a better choice.

Thermometers

To be always on the safe side, use a common digital thermometer with a remote probe. Set the alarm to 145° F (63° C), insert the probe in the thickest part of the fish or fillet, and start smoking. Once you hear the alarm, maintain this temperature for 30 minutes, and rest assured that the product is safely cooked. You may, however, continue smoking longer in order to obtain a stronger smoky flavor. The control of the temperature is less important now; you may go higher, but try to stay at or above 145° F (63° C) internal meat temperature. At this temperature, the food can be kept for a few hours without the danger of bacteria growing again. Hot food is kept at this temperature in restaurants.

Factory Made Smokers

The big advantage of electric thermostatically controlled smokers is the ease with which the high temperatures can be maintained. Unfortunately, those units have very little usable space inside, so you will not be able to hang a large fish.

Why Smoke Fish

You save money. Smoked fish is an expensive item as it requires time and extra processing steps. Compare the price of fresh and smoked salmon. It is still the same fish, but the price has doubled. You can smoke any fish you like. Manufacturers smoke and can only fish that have proven to be profitable. They will not take the risk of smoking red snapper, perch, or scallops.

How Long to Smoke?

How long to smoke is an open question. Well, there isn’t one universal time; use your own judgment and keep records. The size of the fish will be a deciding factor, but you can estimate smoking time by checking the color of the smoked fish as well. For example, for a small fish like a mullet, 2-3 hours of hot smoking is plenty. It is safer to smoke for two hours and then check the results. Over-smoked fish will acquire a bitter smoked flavor that will not go away, so it is better to be on the safe side. A fish can be smoked and cooked within 20 minutes at 662° F (350° C), but its smoky flavor will be weak. Smoking needs time; about 2 hours is sufficient for a typical-sized hot smoked fish. This implies that if you want to smoke a 1” fillet for 2 hours, you have to choose cooking temperatures that will not overcook the fish.

When is the Fish Done?

The hot smoking process should finish at a high enough temperature to fully cook the meat and destroy the maximum number of bacteria. At 122° F (50° C), about 70-80% of fish proteins are cooked, but at 140° F (60° C), 95 % of proteins are fully cooked. Cooking to 160° F (72° C) inside temperature produces the best-tasting fish. Coincidentally, this is the recommended safe temperature for cooking red meats. The Food Safety and Inspection Service of the United States Department of Agriculture recommends cooking fish to 145° F (63° C) or higher for 30 minutes or longer.

Note Different size fish can be smoked at the same time, however, thicker fish will require longer processing time.

A reliable test is to insert a fork or knife into the thickest part of the fish and twist. The flesh should flake. In addition:

- The belly fin can be easily removed with fingers.

- The flesh of the belly must be white and not glassy.

- It is difficult to hot smoke a large fish like carp or red fish in one piece. The solution is to split the fish lengthwise or cut across into steaks. Then, the fish can be smoked/cooked at 266° F (150° C) for about one hour. Basically, such a method can be described as barbecuing fish with smoke.

Cooling

Smoked meats and sausages are usually showered with cold water to let them pass through the danger zone 140-60° F (60-16° C) as fast as possible. Afterwards, they can be refrigerated. The fish smoking process ends right inside the danger zone, so in order to preserve its useful life, the fish must be cooled quickly, too.

Showering fish with water is not practical, as much water will be trapped by the body of the fish. A better idea is to place fish in a drafty area or to use a ventilating fan to speed up cooling. Then, the fish should be bagged and refrigerated or frozen. Hot smoked fish must be allowed to cool to at least room temperature, and preferably to about 0°C in a cooler, before packing them. By room temperature, we mean a temperature of around 68-77° F (20-25° C). Fish that is still warm when vacuum packed or packed into ziplock bags will turn flabby and sour and may turn moldy.

Type of Smoke

We can control to a certain degree the quality of the smoke. The smoke can be wet or dry. Wet smoke is produced when the rate of combustion is low. This happens when a small amount of air is allowed to enter smoke generation unit. Using small chips, especially sawdust, will result in low combustion and heavy smoke. Adding wet sawdust will produce even more wet smoke. Wet smoke attracts more resinous and unburnt particles. As a result, when smoking time is long, the product may acquire a bitter taste. Dry smoke is produced by a more complete combustion. The smoke is lighter, and the smoked product develops a good flavor and color. Burning larger chips, chunks, or even log wood will provide more access for the air to enter the burning pile and will result in hotter and cleaner smoke.

Humidity

Commercial smokehouses are equipped with temperature and humidity controls. In many smokehouses, the efficiency of the operation is still dependent on atmospheric conditions. The air can be moist or dry. When the air is moist, the moisture can be removed from the air before it enters the smoking chamber. This could be accomplished by installing a cooling system ahead of the incoming air. If the air is passed over crushed ice, it will be cooled as well. The cooler air can hold less moisture, and we are left with cold, dry air. If this air is preheated, the very dry but hot smoke will enter the smoking chamber. When the air is too dry, for example, smoking during the day in a desert area, a pan filled with water may be inserted into smoking chamber. Presoaking wood chips will bring some moisture, but only for a while. Air speed should not be too great; otherwise, excessive drying of the product results. In home smokehouses the natural draft can be controlled with exit dampers. When smoking at home, we can control humidity by choosing the time of the day. There is more humidity at night than during the day.

Color of Smoked Fish

The color of smoked fish depends on the color of the skin, the length of the smoking, and the type of wood used for smoke generation. Mullet, herring, mullet, blue fish, and mackerel all have different skin and flesh colors, so they will have a distinctive color after smoking. Dark colored fish will be dark after smoking, and silver colored fish will develop a golden or light brown color. The type of wood will contribute to the final color, although up to a certain point.

| Color | Wood |

| yellow-lemon | acacia |

| gold-yellow | maple, linden, beech |

| yellow-brown | oak, alder, walnut |

| reddish | hickory |

The color, however, will become darker as the smoking continues; for example, the light colored fish may develop a yellow color that will change to light brown and brown as the process continues.

Wood for Smoking

Any hardwood is fine, but evergreen trees like fir, spruce, pine, or others cause problems. They contain too much resin, and the finished product has a turpentine flavor to it. It also develops a black color due to the extra soot from the smoke, which in turn makes the smoker dirtier too. And, of course, you cannot use any wood that was previously pressure treated, painted, or commercially manufactured. The type of wood used is responsible for the final color of the smoked product, and it can also influence its taste, but only to a small degree. The type of hardwood used for smoking is not as important as people like to imagine. All fruit and citrus trees have a light to medium sweet flavor and are excellent for poultry and ham. Many say that cherry wood is the best.

It is a fact that alder was popular for smoking salmon in the Pacific Northwest, and it is a fact that it is popular in Poland among hobbyists and commercial producers. However, alder wood owes its popularity not to any secret components but to a simple fact that is plentiful in those areas. It grows well there, and it produces satisfactory smoke. The popularity of a particular wood is directly related to whether it grows in a particular area. It would be most illogical to order wood over the Internet when a local hardwood is free for the picking. Beech is common in Germany and in Poland and is used by commercial plants, very often mixed half and half with alder. Alder, oak, and poplar are popular in Russia. Oak was popular for cold smoking fish in England and still is the best wood all around. Many wood chip manufacturers stay away from oak as it makes their cutting saws dull in no time at all. However, if you are willing to use an ax and cut some oak chips, it is a great wood for smoking. Oak will paint the product brown. Hickory is good but unknown outside the USA. Hickory leaves a reddish tint.

Fruit and nut trees are good for smoking, however, they are not as abundant as alder or oak. This makes them expensive. Combining different woods will create customized tints of color; for example, oak and hickory will produce a pretty reddish-brown color. Walnut, which has a heavy smoke flavor, can be mixed with apple wood to create a milder version. Alder imparts yellow color so it is especially good for fish. Keep in mind that the deepness of color is related to the length of smoking. Avoid using soft woods like pine, cedar, spruce, and other ever green needle trees. Those trees will produce dark color. Resins from these trees will leave an unpleasant flavor on the fish. Be smart, look around, and use hardwood, which is available for free. The quality of smoked fish depends more on curing or drying than on the type of wood used for smoking. Always store sawdust very dry. Sawdust is very dense and easily develops moisture pockets, which can hold large numbers of mold spores. These molds can adhere to the surface of the fish during smoking and can multiply during storage. The shelf life of the product will be greatly decreased.

Summary of Critical Issues

- Smoke is inhibited by the skin and the scales.

- Smoke is inhibited by the fat, lean fish smokes faster.

- The more air available to wood for smoking, the higher the temperature. Burning sawdust results in the lowest temperature and the densest, but the dirtiest smoke. A lot of soot is produced.

- Hardwoods produce the cleanest smoke.

- Evergreen coniferous and needle type trees produce are rich in resin and produce low quality, turpentine flavor smoke.

- Dry wood should be used for cold smoking.

- Soaked wood chips may be used for hot smoking.

- Wet wood produces smoke that is rich in vapor, soot, and many unburned particles. The smoke is dark and heavy, consisting of large particles.

- Meat with a wet surface acquires smoke faster. Unfortunately, the heavier particles and soot are easily attracted. The resulting color is dark and the flavor inferior.

- The fish that was dried before smoking will develop the most attractive color.

- The smoked fish develops the best color in about 2 hours; however, after the process is stopped, the development of color will still continue and will be the strongest after about 10 hours.

- A darker color develops when the smoking time is increased and the thicker smoke is applied. Increasing the smoking time and applying the thinner smoke will produce the same results as decreasing the smoking time and applying the denser smoke.

- The best quality fish is produced when hot smoke does not exceed 180° F (82° C).

Smoking Shellfish

Shellfish, such as mussels, clams, oysters, and shrimp are very delicate and require short brining and smoking times. Overcooking makes them rubbery. Detailed instructions are included in the Smoked Shellfish section.