Meats and Sausages

Glass Jars

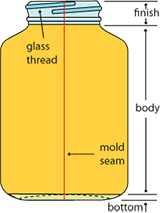

When Nicolas Appert struggled with his first attempts at canning, neither glass jars nor tin cans were around, so he was using wide mouth bottles and corks which were secured with wire. John Mason patented the continuous-thread closure on November 30, 1858. In 1883 William Charles Ball and his brothers switched over from tin containers to glass containers for storing lard and oil. In 1886 they started to use glass containers for storing fruits. In 1903 Alexander Kerr started to use wide mouth glass jars. Later in 1915 he invented a smaller, flat metal disk with a permanent composition gasket. His two-part lid system transformed home canning safety and is still in use today. Glass jar is made from three separate molds: finish, body and bottom, which are then molded together. The connection is known as mold seam and may be mistaken for a crack in the glass. Each part has its own mold seam and they may or may not be aligned in a straight line.

The basic parts of a glass jar.

Use only standard jars intended for home canning. Never use jars from commercial food products. Regular and wide-mouth Mason-type, threaded, home-canning jars with self-sealing lids are the best choice. They are available in 1/2 pint, pint, 1-1/2 pint, quart, and 1/2 gallon sizes. The standard jar mouth opening is about 2? inches. Wide-mouth jars have openings of about 3 inches making them more easily filled and emptied. Half-gallon jars may be used for canning high acid juices. Regular-mouth decorator jelly jars are available in 8 and 12 ounce sizes. With careful use and handling, Mason jars may be reused many times, requiring only new lids each time. When jars and lids are used properly, jar seals and vacuums are excellent and jar breakage is rare.Most commercial pint and quart size mayonnaise or salad dressing jars may be used with new two piece lids for canning acid foods. However, you should expect more seal failures and jar breakage. Seemingly insignificant scratches in glass may cause cracking and breakage while processing jars in a canner. Mayonnaise-type jars are not recommended for use with foods to be processed in a pressure canner because of excessive jar breakage. Other commercial jars with mouths that cannot be sealed with two-piece canning lids are not recommended for use in canning any food at home.

Glass Jar Types

There are three types of glass jars and closures currently used in food packaging:

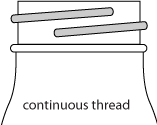

- The continuous-thread jar.

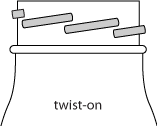

- The twist-on jar.

- The press-and-twist jar.

Continuous-Thread Jar With Single Lid

The jar and lid are both threaded in one continuous bead around the entire circumference of the opening; also referred to as "screw-on". There is less likelihood of over-tightening a screw-on closure. Continuous-thread jar may have a one part lid, for example mayonnaise jar or it may have closure consisting of two parts: a lid and a screwband, for example a typical canning Mason jar.

All types of jars can have a vacuum indication button built into the lid.

Many believe that a canning jar must be embossed on the sides with the word Mason, Ball or Kerr. Well, what is the real Mason jar? Any jar with a continuous-thread closure will do the same job as long as it is made strong enough to withstand the thermal shocks encountered in the canning process.

Continuous-Thread Jar With Two-Piece Lid

The advantage of glass jars with two-part lids lies in the fact that those jars have been around in the USA for so long that they have become an unwritten standard in home canning. There are three sizes to choose from: 1/2 pint, pint and quart, two lid sizes will fit all jars, and the jars can have a regular or wide mouth opening. The lids come with one universal sealing compound and the jars have been perfected over the years. If used properly they create a perfect seal every time.

It is our recommendation to use wide mouth jars for canning meat as many products will hold their shape better when removed from a jar, for example meat loaf. Then they can be browned or roasted and they will look much better on a plate. There are meats that are eaten cold, for example head cheese or meat jelly. They may even have food decoration in the bottom which will be on top of the piece when it is flipped over. You can use regular jars for soups, beef stews or products which are made of many smaller components, for example chili con carne and beans. However, canning is simpler when only wide mouth openings are chosen. In addition, the same diameter lid and screwband fit both, pint and quart size jars.

Lid Selection, Preparation and Use

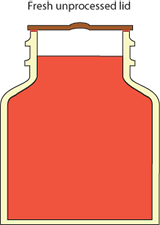

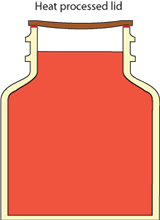

The common self-sealing lid consists of a flat metal lid held in place by a metal screw band during processing. The flat lid is crimped around its bottom edge to form a trough, which is filled with a colored gasket compound. When jars are processed, the lid gasket softens and flows slightly to cover the jar-sealing surface, yet allows air to escape from the jar. The gasket then forms an airtight seal as the jar cools. Gaskets in unused lids work well for at least 5 years from date of manufacture. The gasket compound in older unused lids may fail to seal on jars. Buy only the quantity of lids you will use in a year. To ensure a good seal, carefully follow the manufacturer's directions in preparing lids for use. Examine all metal lids carefully. Do not use old, dented, or deformed lids, or lids with gaps or other defects in the sealing gasket. Use new lids every time.

The lid goes on top of a jar and is held in place by the screw band that goes over it. The jar lids are usually heated in hot water and kept hot until ready to use. The screw band is secured finger tight as it does not play a major role in the sealing process. If rings are too loose, liquid may escape from jars during processing and seals may fail. If rings are too tight, air cannot vent during processing and food will discolor during storage. Over tightening also may cause lids to buckle and jars to break, especially with raw-packed, pressure-processed food. When a jar is processed the sealing compound softens and covers the rim surface of the jar. However, it remains soft enough to allow the building air pressure to escape from the jar. As the jar cools, the compound hardens and the gasket forms an airtight seal. The slow hardening of the gasket is the reason why processed jars are left undisturbed for 12 hours to cool down. After cooling, the jars are inspected for a tight seal. The metal screw bands have served their purpose and may be left on the jars or removed and used in the next operation. Do not retighten lids after processing jars. As jars cool, the contents in the jar contract, pulling the self-sealing lid firmly against the jar to form a high vacuum. Screw bands are not needed on stored jars. They can be removed easily after jars are cooled. When removed, washed, dried, and stored in a dry area, screw bands may be used many times. If left on stored jars, they become difficult to remove, often rust, and may not work properly again.

Twist-On Jar

Lug is the closure system where the container has multiple threads and the lid has an equal number of lugs or tabs that grip the corresponding threads; also known as "twist-on". There may be three to six lugs depending on the diameter of the cap. Twist-on closures are mainly used by commercial producers, although they are available online as well. In their guides, the USDA mentions only glass with two part lids for home canning, however, all commercial products are canned in jars with a single lid only. Twist on jars (lug type) can be processed much faster by modern machines as the lid is closed with a part turn only. The lug closure (twist cap) can be easily removed and forms a good reseal for storage. Homeowners in Europe use single lid closures and most of them are not familiar with American style two-part lid.

Sealing compound used in continuous thread and twist-on jars is known as plastisol and its composition may vary depending on the application.

Be aware that standard one-piece lids are manufactured for hot-fill temperatures (around 180° F). Then, there are lids manufactured for hot water bath (212° F, 100° C) and the lids that can be used in pressure canners (over 212° F, 100° C). The conclusion: do your homework first, then pick up the lid suitable for your application. Continuous thread single closure jars are commonly used in Europe for hot filling acidic foods such as jams or jellies. After the jar is filled, it is inverted for for a few minutes, then left to cool by itself. Inverting the jar allows plastisol make contact with hot contents which softens the sealing compound. Upon cooling the vacuum forms inside and the jar is sealed.

Fillmorecontainer, www.fillmorecontainer.com carries single piece canning lids with a vacuum indicating button for pressure canning. Those lids incorporate a sealing compound which has been designed for processing at higher temperatures.

Molded plastisol provides the seal along the top and and sides surfaces of the glass container finish.

Recommended Glass Jars for Home Use

| Common Name | Capacity | |

|---|---|---|

| Fluid Ounces | Milliliters | |

| 1/2 Pint | 8 | 236 |

| Pint | 16 | 473 |

| Quart | 32 | 946 |

Containers larger than quart glass jars or No. 3 cans are not recommended for home use because of difficulty of thorough heat processing. As a result some parts of the food might not be sufficiently heated and may not kill bacterial spores.

Testing Sealed Jars

Most two piece lids will seal with a "pop" sound when cooling. When the canning jars have cooled down, test the lid. A canning jar is properly sealed if the lid is curved down or remains so when pressed. If it springs back and makes a clicking sound it is not properly sealed.

Another method is to tap the center of the lid with a spoon. A clear ringing sound means a good seal. A dull sound signifies that a jar does not have a tight seal or that the food is touching the lid. Hold the jar and look at it. If no food is touching the lid, the jar does not have a tight seal and cannot be stored. When the jars have completely cooled, the screw bands are removed. Due to humidity they may rust during storage making them difficult to remove. The bands do not form the seal, the canning lids do. Remove the screw bands, wash, dry and store them until needed again. Check seals. Improperly sealed jars can be reprocessed within 24 hours using a new sterilized lid and the same processing time. If they are not remade, they should be refrigerated and used within 1 month.