Meats and Sausages

Smoke Generator

A smoke generator is any type of device that can produce smoke. A stainless steel pan or a small metal box with holes, loaded with wood chips, become smoke generators the moment the chips are heated enough to produce smoke. They can be found in small, very simple one-unit smokers such as metal drums, wooden boxes, or even in carton boxes. Medium-sized smokers usually have smoke generators attached to or standing next to them. They include a wood chips/sawdust hopper, a feeding mechanism, a blower, and a connecting pipe. They usually operate on electricity, but also on natural or propane gas. A free-standing firebox, which is connected to a large smokehouse with a 6" diameter clay or metal pipe, or a dug-in ground trench can also be considered a smoke generator. Then, there is a small but very effective generator that works on the "venturi" principle.

Venturi Smoke Generators

A smoke generator is needed for smoking meats or sausages. Generating smoke in small home units is a time-consuming task, which is probably not as difficult as maintaining the correct temperature inside. However, generating smoke can be either a boring and annoying process or an enjoyable experience. That task became easier to accomplish when venturi smoke generators started to appear around 2005. First in New Zealand, then in the USA, Poland, and other countries.

Imagine somebody smoking a cigarette that sits next to the partially open window in a fast traveling car. The fast-moving air outside creates a vacuum next to the window and pulls smoke out of the car. The same principle is used in venturi smoke generators, where the pressurized air from an aquarium air pump is injected into a container that is filled with wood chips. The lowest layer of wood chips keeps on burning, producing smoke. As it burns away, it turns into ash that sinks to the bottom of the hopper. Then, the layer above starts to burn. The top layers cannot ignite as they are not exposed to the fresh air that is needed for combustion. However, fresh air enters through the holes at the bottom of the smoke generator, so the chips above can keep on burning.

Since the unit is only about 12" tall, there is not enough draft to force the smoke into the chamber. This is when the aquarium air pump comes to the rescue. The smoke generated rises slowly, but most of it is sucked away by the air that comes out from the aquarium air pump nozzle. The air nozzle is aimed towards the opening that leads into the smoking chamber, and this is the only direction for the air and smoke to travel.

There are units for sale in New Zealand (Venturi 500, 400), Poland (Roger), or in the USA (Smoke Daddy™), and although they may differ slightly in construction details, the engine that powers them is in all cases the same: an aquarium air pump. There are different types of venturi smoke generators, and they all work well.

A big advantage of Venturi smoke generators is that they accept different sizes of wood chips, so they are not locked into any particular brand of a smoker.

Low Nozzle Smoke Generator

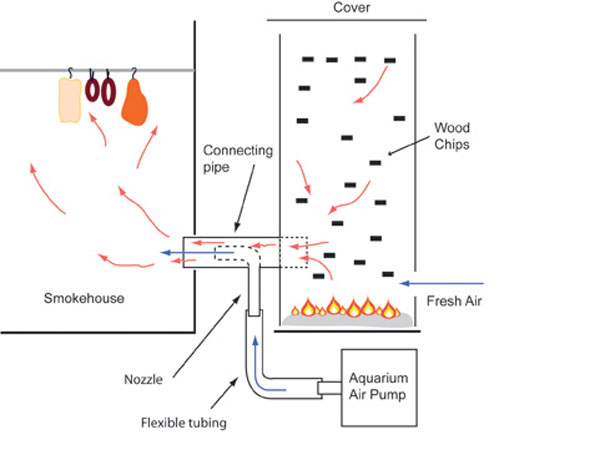

This is a typical venturi smoke generator. The connecting pipe is placed in the lower part of the unit; therefore, the smoke generator and smokehouse are at the same level. Such an arrangement works out well with small smokers as the smoke enters at the bottom of the chamber.

Low nozzle cofiguration smoke generator.

The top of the container (cover) is loosely attached but should make a reasonably tight connection to prevent the loss of smoke. A hole is made for the pipe that connects the smoke box with the smokehouse. The connecting pipe can be considered the smoke delivery channel. This pipe may be inserted loosely, threaded on both ends and secured with nuts, threaded into the smokehouse wall and the wall of the wood-burning container, etc. This will depend on your technical abilities and the fanciness of the design.

The disadvantage of this design is that larger wood chips can get lodged on top of the pipe and prevent more chips from dropping down. This will stop the fire. For that reason, the length of the pipe in a smoke box should be kept to a minimum. Secondly, the pipe’s opening must be somehow protected, otherwise, wood chips may enter inside and block the intake of smoke. Thirdly, this design does not contribute to the natural draft of the smokehouses because the smokehouse and the firebox are placed at the same level. This means that when the pump is off, the system will have little power to suck the smoke up.

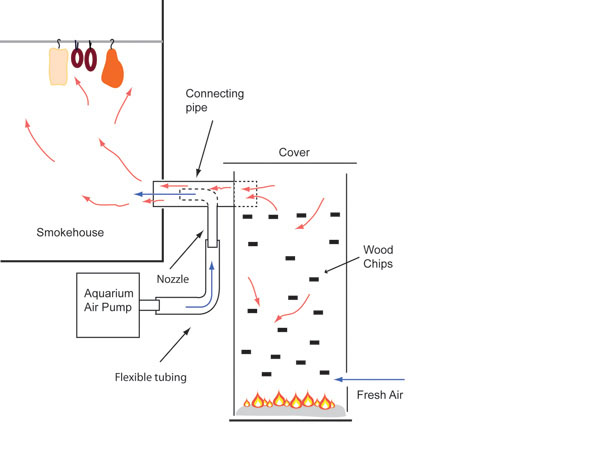

Those minor flaws of the above design can easily be corrected by flipping the smoke box 180° on its horizontal axis and placing it either below the smokehouse or raising the smokehouse higher. Of course, the fresh air supply holes must be present in the top and the bottom of the firebox and are simply covered with tape.

The high nozzle configuration induces stronger draft, providing that the smokebox is placed below the smokehouse. Even with a pump off, there should be enough natural draft to allow a thin smoke production. The greater the distance between the fresh air inlet and the smoke exhaust, the stronger the draft.

High Nozzle Smoke Generator

High nozzle smoke generator.

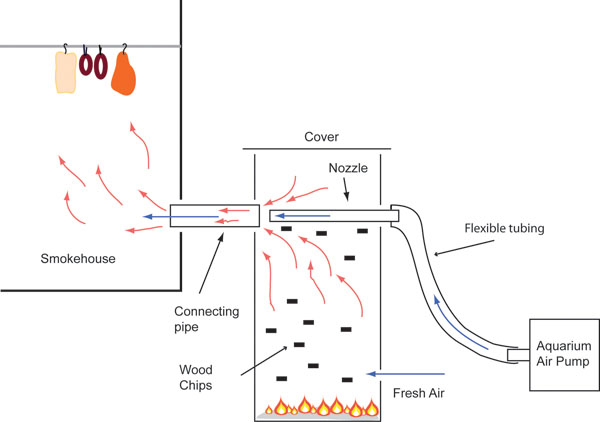

Straight Injector High Nozzle Smoke Generator

This is a simple but effective smoke generator. Smoke Daddy™ smoke generators operate on this principle. The air flowing through the nozzle exits about 1/4” before the connecting pipe, which is of a larger diameter. In this little air gap a sufficient vacuum is created to suck in the smoke into the connecting pipe. The heart of the system consists of 3 parts: an air pump, an air nozzle (metal tube), and a connecting pipe. Those parts can be connected together in many different ways. They can be threaded, nut secured, or permanently welded.

Straight injector high-nozzle smoke generator. Since the diameter of the air-supplying nozzle is only about 1/4 of an inch, it will get dirty due to unburnt smoke particles, soot, tar, and other ingredients. They will be in a liquid state when the nozzle is still warm but will solidify upon cooling, impeding smoke flow during the next session. Cleaning this nozzle should be the last part of the smoking process; preventive maintenance is a good term for it.

The venturi principle is explained in our section dealing with Gas Burners.