Meats and Sausages

Masonry Smokehouse #5695

The following smokehouse was designed in 1965 by the North Dakota State University and the U.S. Dept. of Agriculture. This is a big walk-in smokehouse requiring a foundation reaching below the frost line. This is the depth where water can still be found frozen depending on a particular geographical location.

General view

Description

This plan is very similar to the # 5695 Frame Smokehouse, the difference being in the materials used for construction. This is a classical design of a smokehouse that has been used in Europe and later in the USA for centuries. It is about 10’ high, with ventilation on both sides, a # 30 mesh screen on the inside, and a hinged door on the outside. There is a removable utility bench inside and a barrel with salt in the corner.

Floor plan

The smokehouse is built using standard-size concrete blocks 8” x 8” x 16”, which make the project inexpensive and easy to complete. It is almost like building a small house – foundation, concrete walls, and a wooden roof that can be covered with shingles. The floor is made of 4” concrete, and the door is covered on the inside with sheet metal.

Cross section

The advantage of this design is excellent insulation and a very strong design. Using gas for fuel and placing two strong burners inside it will make it possible not only to smoke products inside but cook them as well to the required inside meat temperature of 152° - 160° F.

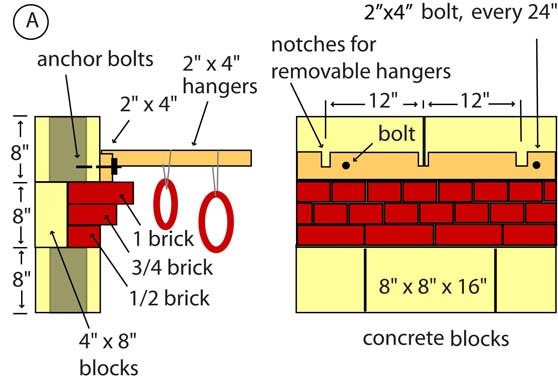

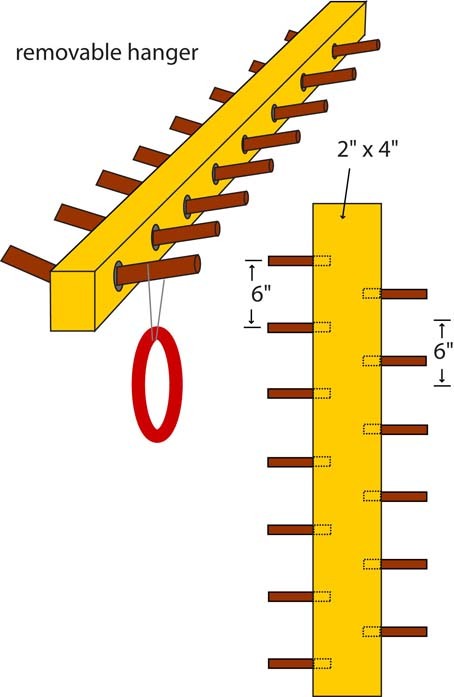

Supports for hangers

This type of smokehouse is overkill for a home sausage maker but becomes a very attractive proposition for someone who wants to make products for sale. Commercially made smokehouses of this capacity will be very costly, as they are made of stainless steel and come with computer control, automatic showering, and all types of advanced settings.

All those functions can be easily accomplished by using a few thermometers and obeying the basic rules of smoking meats. The proper curing of meats before smoking is more important than all the bells and whistles that come with an expensive industrial unit. Another advantage is that there is almost no maintenance as the smokehouse is so simple. If including this type of smokehouse in a regular meat processing operation it would be a good idea to submit the plans to the local fire department to see what changes may be needed. They may require a concrete slab roof instead of the framed one, a different thickness of the floor, or some additional drain to be installed. This type of design has proven itself for hundreds of years and cannot be beaten. Many professional butchers use their own brick layered smokehouses with a great deal of success.

Hangers

The above information is reprinted with permission from the book Meat Smoking and Smokehouse Design.

Note See Smoke Houses in the main menu at the top of the page to learn more about building smokers, smoke generation, fireboxes, controls, traditional smokers, and more...