Meats and Sausages

Smoking Meat

The first methods of food preservation were salting, drying, and smoking, although smoking was basically drying meat with smoke since moisture removal and not applying smoke preserved the meat. The meats were either suspended high above a smoldering fire or kept next to it. Smoking meat is exactly what the name implies: flavoring meat with smoke. Using any kind of improvised device does the job as long as the smokehouse is made from environmentally safe material. As long as smoke contacts the meat surface, it will impart its flavor to the meat. The strength of the flavor depends mainly on the time and density of the smoke. Smoked meats are usually eaten cold at a later date. Many great recipes require that smoked products hang for a designated time to lose more weight and become drier. It is only then that they are ready for consumption.

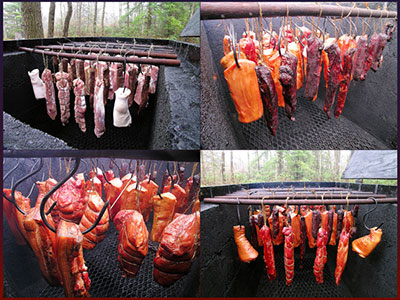

Waldemar Kozik smoking meats in Catskill Mountains, N.Y.

Why Smoke Meats

Smoking offers many improvements to meat. Besides enhancing the taste and look, it also increases its longevity and helps preserve the meat by slowing down the spoilage of fat and the growth of bacteria. Smoking meat for longer leads to more water loss and results in a saltier and drier product. Given that bacteria hate salt and need moisture to live, this makes meat bacteriologically safe, increasing its shelf life. Man discovered that in addition to salting and curing meat with nitrates, smoking was a very effective tool in preserving meats.

The advantages of smoking meat are numerous; smoking:

- Inhibits the growth of bacteria by removing some of free water.

- Prevents fats from developing a rancid taste.

- Prevents mold from forming on fermented sausages.

- Extends the shelf life of the product by evaporating moisture, which bacteria need for growth.

- Improves meat's taste and flavor.

- Changes the color; smoked meats shine and look better. Smoked meat becomes light brown, red, or almost black depending on the type of wood used, heating temperatures, and total time of smoking. Nothing improves the quality of the fish as smoking; smoked fish develops a beautiful golden color and a different taste.

The smell in an ethnic meat store specializing in smoked products can be overwhelming. This experience is not shared with our supermarkets since their products are rarely properly smoked; besides, they are vacuum-sealed, preventing us from sensing the aroma. Certain classical sausages are smoked for up to 3 days, and in today’s era, it is hard to imagine a manufacturer that will do that. To survive the frantic pace of today’s market, water is pumped into the meat, chemicals are added for aesthetic and preservation reasons, and smoking is virtually eliminated by adding liquid smoke. As long as the ingredients are not on the list of chemicals that present danger, the Food and Drug Administration does not care what goes into the meat. Taste plays a secondary role; as long as the price is good, people will buy the product, and supermarkets will keep renewing orders. Smoking to preserve meat’s qualities is of less importance today because we can keep the product in a refrigerator or almost indefinitely in a freezer. Originally, curing and smoking were only for preservation purposes; today, it’s done for the love of its flavor.

Smoking - Barbecuing - Grilling; What is the Difference?

When meat comes in touch with smoke for an extended period of time, it will acquire a smoky flavor, regardless of the temperature or design of a smoker. However, different temperatures will affect the meat's texture, color, and shelf-keeping properties. Although barbecuing and grilling will also develop a smokey flavor, however, they have very little in common with smoking techniques employed in smoking deli-type meats and sausages. The main factor separating them is temperature.

| Smoking - very low heat | 52° – 140° F (12° - 60° C) | 1 hr to 2 weeks, depending on temperature |

| Barbecuing - low heat | 190° – 300° F (93° - 150° C) | low and slow, few hours |

| Grilling - high heat | 400° - 550° F (232° - 288° C) | hot and fast, minutes |

Methods of Smoking

The temperature of smoking, which is basically a cooking process, affects the texture, taste, and look of the product. At around 104° F (40° C), meat proteins become denatured (cooked), and collagen starts to swell. Throw an egg on a frying pan and start increasing the heat. Egg white, which contains about 10% of the protein, envelops and protects the yolk. In the beginning, it is clear and transparent, but with increasing heat, it becomes white and opaque. Its proteins become cooked, and the texture hardens. The same happens when the meat is hot smoked, but not during cold smoking, whose temperature is below 86° F (30° C). Those changes in meat's texture are the reason why there are different methods of smoking:

- Cold smoking - flavoring and drying process without additional cooking.

- Warm smoking - can be at the upper limit of cold or lower limit of hot smoking; in between range, less popular. The temperature range is often used for conditioning (drying) meats before applying smoke.

- Hot smoking - flavoring process which is followed by cooking.

Those methods are described in more detail on separate pages; the pages are listed in the Menu above.

Generally, we may say that smoking consists of two steps:

- Smoking. Top-quality meats are cured before they are subjected to smoking. Smoking may or may not be followed by cooking.

- Cooking. This step determines the design and quality of your smokehouse, as it needs temperature controls, a reliable heat supply, and good insulation to hold the temperature when the weather gets cold. This is needed if meats will be baked in a smokehouse after smoking. If cooking is performed outside the smokehouse, the unit can be incredibly simple, for example, an empty cardboard box. Then, the meats are cooked in water, which is the most popular and practical method.

After smoking is done, we increase the temperature to about 170-185° F (76-85° C) to start baking in a smokehouse. The smoked meats must be cooked to 154° F (68° C) internal temperature, and here, the quality and insulation of the smoker play an important role. Nevertheless, the main smoking process is performed below 160° F (71° C), usually at 140° F (60° C). Cooking in water (poaching) is performed below the boiling point of water, usually at 176° F (80° C).

We know now that the smoked meat must be cooked, but does that mean that it must be cooked inside of the smokehouse? Don’t we have wonderfully designed and factory-built electrical or gas stoves inside every kitchen? They are insulated, have built-in temperature controls, and are almost begging for these smoked sausages to be baked inside. How about putting your smoked meats into a pot full of hot water and cooking these products on top of the stove?

Traditionally smoked meats almost always come from cured parts of pork. The most popular large cuts used for smoking are ham, bacon, butt, loin, back fat, and smaller parts such as hocks and jowls. Ribs are normally barbecued. Due to their large size, those popular cuts require longer curing times, although those times can be somewhat shortened when needle pumping precedes the common wet curing method. Hams can be dry or wet cured, butts and loins are normally wet cured, and bacon and back fat are commonly dry cured. Trimmings end up making sausages.

Curing develops a peculiar curing flavor which is in demand by the knowledgeable consumer. Before you bite a slice of traditionally cured smoked ham or sausage, you will smell a peculiar aroma. It is called the curing flavor, and it can only be developed when salt and sodium nitrite (Cure #1) are given sufficient time to react with meat.

There are many pages dedicated to curing meats in the Making Sausages section. Follow this link to learn more curing meat for sausages

Smoking Without Nitrates

For those who smoke meats without cures, it will be advisable to smoke them at temperatures well above the danger zone (>160° F, 72° C). Such a product will not be pink but will exhibit a typical grayish color of cooked meat. Adding a nitrate cure brings many benefits, one of them being the prevention of food poisoning, known as botulism. Barbecued meats are smoked at much higher temperatures, which eliminates the danger of Clostridium botulinum producing toxins.

Those who insist on smoking meats without nitrates, should be aware that the internal meat temperature trails the temperature of the smokehouse by about 25° F and to be on the outside of the danger zone, the smoking must be performed at temperatures higher than 170° F (77° C) which in our opinion becomes cooking with smoke. Clostridium botulinum bacteria need moisture, warm temperatures, and the absence of oxygen. These are prevalent conditions in a small self-contained smoker, where incoming air is kept at a minimum in order for the sawdust to smolder and not to burst into flames. A large outside smokehouse with a separate fire pit is at a smaller risk as there is an ample flow of fresh air that enters the smoking chamber together with the smoke. Using dry wood increases safety as less moisture will be created.

Smoking Temperatures

Smoking temperature is one of the most important factors in deciding quality. There is no steadfast rule that dictates exact temperature ranges for different types of smoking. A few degrees one way or the other should not create a problem as long as the hot smoking upper-temperature limit is not crossed. Crossing this limit will significantly affect the look and taste of the product. When smoking, the inside temperature of the smoker cannot exceed 170° F (78° C) for any extended time. At this temperature, fat starts to melt quickly. Once it melts, the sausage inside will be a mass of bread crumbs, have a greasy outside, lose its shine, and have an inferior taste. If the internal temperature of the sausage was too high during smoking or cooking, your sausage:

- Is greasy on the outside.

- Contains spots of grease under the sausage.

- Is too shriveled and wrinkled.

- Has lost its shine and looks opaque.

- Is crumbly inside with little empty pockets.

The fats start to melt at very low temperatures, and we don’t want them to boil and leak through the casings. When faced with excessive temperatures, fats begin to melt, and there is no way to undo the damage.

Smoke Deposition

The amount of smoke deposited on a product is influenced by:

- Smoke density - the thicker the smoke, the faster the rate of smoke deposition.

- Smokehouse relative humidity - high humidity favors smoke deposition but inhibits color development.

- The surface condition of the product - moist surface favors smoke but limits color development.

- Smokehouse temperature - higher temperature favors smoke deposition rate.

- Air draft - sufficient air velocity is needed to bring smoke inside. Too fast air might reduce smoke density, and not enough airspeed and product may be over smoked. Usually, a compromise is reached.

How Long to Smoke?

There isn’t one universal time; use your own judgment and keep records. When cold smoking, the times are very long, days or even weeks, as the purpose of cold smoking is to preserve the product for future use by removing moisture. There are not many people today who will have the time or patience to smoke products in this manner, but those who will try it will be richly rewarded by creating products of different textures and flavors. When hot smoking, the times are short as we smoke and then cook the product, trying to achieve the best flavor. The diameter of the meat piece or sausage will be a deciding factor here, but you can estimate smoking time by checking the color of the smoked piece as well. Sausages have a small diameter, so the times are relatively short. For example, Kabanosy meat stick is stuffed into 24-26 mm sheep casings, and 1 hour of smoking time is plenty. Polish Smoked sausage stuffed in 36 mm hog casings will need about 1-2 hours. If the color of the sausage is yellow, it is lightly smoked; if it is light brown, the sausage is nicely smoked; if the color becomes dark brown, the sausage is heavily smoked.

Remember that hot smoking is not a preservation method; hence, the meat is not safe to consume until it is cooked. Said that it makes no difference whether the sausage is smoked for 15, 30, or 60 minutes.

Manufacturing Process

The process of making smoked products basically follows the steps for making sausages:

- Meat selection

- Curing

- Conditioning/drying

- Smoking

- Cooking

- Cooling

- Storing

Sausages, in addition, will require extra steps, which are grinding, mixing, and stuffing.

All these steps are covered in detail in the Sausage Making section.

Fish, poultry and wild game are covered in the Fish, Poultry and Game sections.