Meats and Sausages

Comminution and Grinding

The purpose of the comminution process is to cut meat down to the required particle size. The typical machines are:

Dicer

Dicer cuts into uniform .-size cubes that may be used in different dishes or specialized sausages. For example Polish Krakowska sausage is done with visible chunks of meat. It is very unlikely that a hobbyist will need such a machine as he can perform the same function with a sharp knife.

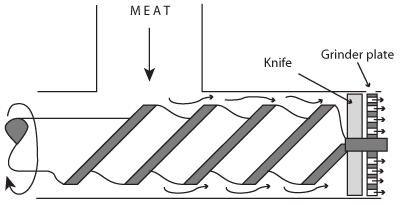

Grinder

Grinder is the most popular machine that has been around for a long time. There are many commercial brands on the market. Some units can grind and mix at the same time, which saves time and space. They differ mainly in output capacity. The grinder, as the name implies, grinds meat and forcefully pushes it through the plate; it does not produce an outstanding clean cut. There is a large amount of pressure on meat in the feed chamber. This leads to tearing between the auger and the walls of the chamber. As a result, the meat is not cut as clean as with a bowl cutter. Most grinders can accommodate a variety of attachments to produce different sizes of particles.

It is much easier to grind cold meat taken directly out of the refrigerator. Ideally, meat should always be chilled between 32-35° F (0-2º C) for a clean cut. The fat should be partially frozen or a smeared paste will be produced. When a recipe calls for a second grind, refreeze the first grind and then grind it again. To produce a clean cut, the knife must always be sharp. When making emulsified sausages, this operation may be repeated 2-3 times.

At home the manual grinder is the machine of choice.

There are basically 5 types of hand-operated grinders: No 5, 8, 10, 22, 32 , the most common being 10, 22, 32 and the most popular # 10.

|

|

|

|

| Model | # 10 | # 22 | # 32 |

| Plate diameter | 2-3/4" | 3-1/4" | 3-15/16" |

| Center hole | 3/8" | 7/16" | 9/16" |

| Knife (square hole) | 7/16" | 1/2" | 9/16" |

#22 and 32 size grinders are heavy enough to rest on the table, but they are usually clamped to it. All of the above grinders employ a variety of accessories, such as grinder plates, knives, stuffing tubes, jerky attachments, and more.

All of the above work fine, but for grinders, the bigger the better. Bigger models have a larger throat, and they will grind the meat faster. However, they are also heavier, more expensive, and require more space to store. The knife must be sharp. otherwise the meat will smear. The grinding becomes almost impossible when the connective tissues wrap around the knife, preventing further cutting. The locking ring on a grinder head should be tight. After a while, the meat will lubricate the grinder, and the crank will begin to turn with ease. Bear in mind that the grinder, whether electric or manual, generates heat, and if it were washed in hot water, it should be cooled off before use.

Home grinders come in the following sizes: 8, 10, 22, 32, number 10 being most popular. It is a fine general-purpose grinder for making smaller amounts of sausage. If you think about mincing 20 lbs. of meat or more get #32. It has a bigger throat, bigger knife and bigger plate diameter. If the recipe calls for a large grinder plate like ¾” and you don’t own it, dice meat with a knife, this is how we made sausages in the past.

What grinder to buy?

Although an electrical machine looks impressive, the question to ask is how much meat are we going to process? Manual grinders are wonderfully designed and very efficient and very inexpensive machines. On the other hand, small home-type electrical models cost more and work twice as fast at best. The only difference is that you don’t have to exercise your hand for 5 minutes. To get any significant output (50 - 100 lbs. per minute), you have to buy a bigger commercial model which is heavy and expensive. It is our personal opinion that it is wiser to invest extra money on a quality piston stuffer and grind meats manually. These are general estimates for the output capacity of different grinders:

| Type | Capacity in lb per min. |

|---|---|

| # 10 | 2-3 |

| # 22 | 3-4 |

| # 32 | 5 |

| Type | Capacity in lb per min. |

|---|---|

| # 10 | 5 |

| # 22 | 9 |

| # 32 | 12 |

The majority of recipes on the Internet ask for between two and five pounds of meat. This means that most people use less than one pork butt (around 6 lbs.) of meat. Number 32 manual grinder will perform this task in 1½ minutes. The number 10 grinder will do it in 2 minutes. An electrical model will be faster but what’s the hurry? If you plan to make 50 pounds of sausage, yes, your hand will get tired and the electrical model is a logical choice.

Bowl Cutter

Bowl cutter - also known as buffalo chopper or silent cutter, cuts meat very finely and is a must-have machine for commercial production of emulsified products such as bologna or hot dogs.

The resulting friction generates so much heat that the meat will boil and cook. To keep the temperature down the flaked ice is added to the mixture. As the meat is finely comminuted, a lot of protein is released, which in combination with salt and phosphates, can easily absorb melting ice and resulting water. The mixture becomes a fine paste, which, after stuffing, becomes a hot dog, bologna, or any emulsified sausage.

The bowl cutter can be employed to make any sausage except fermented or air-dried products. The technology of making these products is based on the removal of moisture; therefore adding ice to the mixture will jeopardize the safety of the sausage.

Grinding Meat for Sausages

The fat is usually ground through a plate with very small holes, and if not partially frozen, a smeared paste will be produced. The locking ring on a grinder head should be tight and the knife must be sharp, otherwise the meat will smear. Otherwise, we would have meat smearing, and the sausage would look greasy even when lean meat was used. Ideally, meat should always be chilled between 32-35°F (0-2ºC) for a clean cut. Since refrigerator temperatures are roughly 38-40°F (3-4º C), we should place the meat in a freezer for about 30 min just before grinding. In domestic conditions, we could choose to cut the meat either during the early hours of the morning or during late evenings when temperatures are not higher than 70°F (21°C).

After we are done cutting the meat, we should separate it into different groups: lean, semi-fat, and fat. The lean meat should be separated from the fat. As a rule, lean meat is ground coarsely, while fatty cuts are ground finely. This way. the sausage is lean-looking and the fat is less visible. Grinding cold meat directly out of the refrigerator is much easier. Then, they should be placed back into the refrigerator. It is possible to purchase minced meat in a supermarket, just make sure it has been minced on the day of the purchase. Such minced meat should be processed no later than the following day.

The question may arise: why do we grind different grades of meat through different plates? It will be much easier to use a 3/8” plate for everything.

There are many reasons for it:

- You could do just that if you had only high-grade meats, let’s say pork class I (ham) and pork class II (butt). With such fine meats, you would not get any pieces of bone, gristle, or sinews that would stick between your teeth. On the other hand, we are left with meat scraps from the lower classes that we would not be able to eat if they were not finely ground.

The second reason is that we want to retain meat juices and water inside the meat, and those lower meat grades with a lot of gristle and sinews are loaded with collagen that helps to do just that. The better grind we can obtain, the stronger binding power meat develops, and this is where a bowl cutter starts to shine. A manual or electrical grinder cuts meat and pushes meat through plate holes, cutting meat but also mechanically breaking it at the same time.

A bowl cutter cuts cleanly without doing mechanical damage to a piece of meat’s structure. It develops a lot of heat, so ice or cold water is added to cool down the meat and rotating knives. That allows the meat to emulsify into a consistency of fine paste that can trap all this ice and water and hold it inside. All scraps of meat with fat, gristles and sinews have become paste, the product will be juicier, and the manufacturer will make more money by charging a customer for this trapped ice and water. This is exactly how we make products such as hot dogs, frankfurters, bologna or liver sausages.

- The third reason is that a lot of fat is added to sausages and will be visible when the sausage is sliced. By grinding fat through a fine plate, the fat will bind with meat and will not be noticeable. Now you understand that there is no rigid, fixed rule regarding grinder plates and that the plate selection depends greatly on the type of sausage that you decide to make.

We chopped meat with knives and stuffed it with fingers through a horn for hundreds of years. And the sausages were great. Queen Victoria of England had her own very strict rules about making her sausages:

- The meat had to be chopped, not ground to prevent the natural juices from leaking out.

- The casings had to be filled by hand, the mixture pressed down through a funnel with the thumbs.

Show Meat

,Some products require meats that are not ground but diced or cut with a knife. Their texture displays solid chunks of meat or fat inside, including even cheese, nuts, or olives. For example, Mortadella is often made with pistachio nuts, some sausages contain whole peppers. Sopressata contains large pieces of fat inside. There are liver sausages that contain cubes of fat or ham sausages with solid chunks of meat inside. This is done for decorative purposes only, Such a sausage does not contain more fat than others. Were this fat emulsified with the rest of the meat, we would not be able to see it, though it would still be inside.