Meats and Sausages

Commercial Pressure Retorts

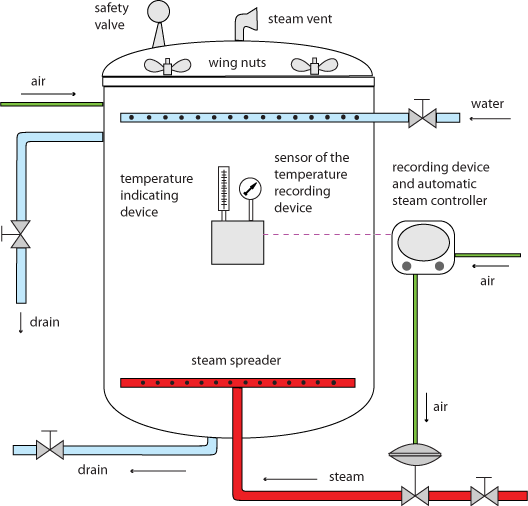

The industry uses the term "retort." Retort can process a few hundred or many thousands cans at one operation. It has to comply with the government regulations, for example each retort must have a temperature indicating device (thermometer) and the temperature recording chart. A pressure canner is a small canner used at home. The main difference between a pressure canner and a retort is the cooling capability of a commercial vessel. At the end of a thermal process the compressed air is injected inside and the retort is flooded with cold water. The cold water immediately lowers the temperature of the product and the compressed air prevents cans from buckling up and the contents of glass jars from boiling over. The temperature of the glass jars must be lowered gradually to prevent the glass from breaking due to the thermal shock. This pessurizing/cooling process allows for a precise control of cooking time and results in a higher quality, longer shelf life product that can be produced at home.

Commercial retorts can be classified into the following groups:

- Still Steam Retorts (vertical or horizontal).

- Still Steam Retorts with Overpressure.

- Hydrostatic Retorts.

- Continuous Rotary Retorts.

- Batch Agitating Retorts.

In addition there are Asceptic Processing and Packaging Systems. Those systems are used for processing liquid foods which are pumped throughout the system. The asceptic system consists of three distinctive areas, all kept in sterile conditions:

- Equipment is sterilized.

- Food is cooked to the commercial sterility stage and stored in a sterile tank.

- Food is packed into sterile containers in a sterile room.

All mentioned above retorts and asceptic systems are covered in the FDA sanctioned Better Process Control course.

Vertical still steam retort.

Like a home pressure canner, the vertical retort is loaded from the top. A wire basket holding hundreds of cans is lowered inside the retort.

NOTE equipment and procedures for pressure processing in still steam retorts are covered in CFR 21, Part 113.40 Equipment and procedures.