Meats and Sausages

Meat Safety

Meat of a healthy animal is clean and contains very few bacteria. The animal’s immune system will destroy any invading bacteria. Once the animal is slaughtered, its defense mechanisms are destroyed and the meat tissue is subjected to rapid decay. Although unaware of the process, early sausage makers knew that once the animal was killed, it was a race between external preservation techniques and the decomposition of the raw meats to decide the ultimate fate of the issue.

Most bacteria are present on the skin and intestines. Bacteria can travel from the animal’s gut through the casing into the meat of a stressed animal. The slaughtering process introduces bacteria into the exposed surfaces. Given time, they will find their way inside, but the trouble starts when we create a new surface cut with a knife. This creates an opening for bacteria to enter the meat from the outside and spoil it. They don’t appear in some magical way; they always start from the outside and work their way into the meat.

Meat Surface Area and Volume Relationship

A. Cube A is 1 inch on each side and has a volume of 1 cubic inch and a surface area of 6 square inches.

B. Three complete cuts (two vertical and one horizontal) produce eight small cubes with a volume of 0.125 cubic inches. Total volume remains the same - 1 cubic inch, but the total surface area has doubled and is 12 square inches. This is what happens when the meat is cut; the surface area increases.

In a large piece of meat, the outside surface is a natural barrier preventing access to bacteria. They have a long distance to travel to reach the center of the meat. Meat muscles are surrounded by connective tissue, which acts as a protective sheath, and so does the outside skin. Duties like cutting meat, grinding, mixing, or stuffing increase meat temperature, and should be performed in the kitchen as fast as possible at the lowest possible temperatures. Otherwise, favorable conditions are created for the growth of bacteria, which will decrease the product's shelf-life.

Food safety is nothing but the control of bacteria, but to do it effectively, we have to learn how bacteria behave first. Once one knows what bacteria like or dislike, safe products with a long shelf life are produced. Let’s make something clear: it is impossible to eliminate bacteria, life on the planet will come to a halt. They are everywhere: on the floor, walls, in the air, on our hands, and all they need to grow is moisture, nutrients, and warm temperature. Given ideal conditions bacteria can double up in numbers every 20 minutes. They grow slower in the refrigerator, but they can still double up in 12 hours. At room temperature, bacteria grow anywhere they have access to nutrients and moisture. Short of deep freezing, it is impossible to prevent bacteria from spoiling meat, all we can do is to create conditions that will slow down their growing rate. The following three factors allow us to control the growth of bacteria and directly influence the safety of meat products:

- Temperature

- Water activity (Aw) - covered in Fermented Sausages

- Acidity (pH) - covered in Fermented Sausages

Temperature Control

Storing and processing the freshest meat at low temperatures is our strongest weapon to fight bacteria. Adding salt and nitrite, increasing meat's acidity, eliminating moisture, and vacuum packing are additional safety measures that help to produce a safe product with the maximum shelf life. Nevertheless, the single most important factor is using the lowest practical temperatures for processing and storing meat. When you answer the telephone and leave ground meat on the kitchen table for 3 hours, it will not matter much if the sausage is grilled a few hours later. But if you buy a 50 lbs box of pork butts to make different sausages for Christmas, now it is a different matter. You can not eat all that meat in a day or two. Some will hang in the kitchen, some in a refrigerator, and some will go into the freezer. It is in your interest to make those sausages safe and last as long as possible. You have to follow Good Manufacturing Practices.

Effects of Time and Temperature on Bacteria Growth

Under the correct conditions, spoilage bacteria reproduce rapidly and the populations can grow very large. Temperature and time are the factors that affect bacterial growth the most. Below 45° F bacteria grow slowly and at temperatures above 140° F they start to die. In the so called “danger zone” between 40-140° F (4-60° C) many bacteria grow very well. Most bacteria will grow exponentially at temperatures between 70° F and 120° F. When bacteria grow, they increase in numbers, not in size. Let’s see how fast bacteria grow at ideal temperature:

| Number of bacteria | Elapsed time |

|---|---|

| 10 | 0 |

| 20 | 20 minutes |

| 40 | 40 minutes |

| 80 | 1 hour |

| 160 | 1 hour 20 min |

| 320 | 1 hour 40 min |

| 640 | 2 hours |

| 1280 | 2 hours 20 min |

| 2560 | 2 hours 40 min |

| 5120 | 3 hrs |

| 10,240 | 3 hrs 20 min |

| 20,480 | 3 hrs 40 min |

| 40,960 | 4 hrs |

| 81,920 | 4 hrs 20 min |

| 163,840 | 4 hrs 40 min |

| 327,680 | 5 hrs |

| 655,360 | 5 hrs 20 min |

| 1,310,720 | 5 hrs 40 min |

| 2,621,440 | 6 hrs |

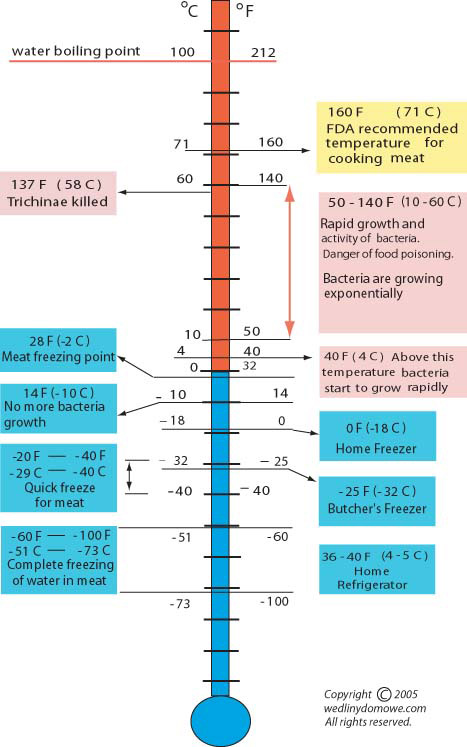

Now it becomes evident what happens to a piece of meat left for many hours on the kitchen table on a beautiful and hot summer day. The following thermometer drawing has been compiled from the data found at the College of Agriculture, Auburn University, Alabama. It shows the time required for one bacteria cell to become two at different storage temperatures. Looking at the drawing, we can see that once the temperature rises above 50° F (10° C), bacteria double every time we raise the temperature by about 5° F. We can draw a logical conclusion that if we want to process meats, we should perform these tasks at temperatures not higher than 50° F (10° C). And those are the temperatures present in meat processing plants. You might say that lowering the room's temperature will still be better. It will, but people working in such conditions for 8 hours a day will find it very uncomfortable.

It can be seen that at 32° F (0° C), bacteria need as much as 38 hours to divide in two. That means if our piece of meat had a certain amount of bacteria on its surface, after 38 hours of lying in a refrigerator, the amount of bacteria in the same piece of meat will double. If we move this meat from the refrigerator to a room having a temperature of 80° F (26.5° C) the bacteria will double up every hour (12 times faster). At 90° F (32° C) they will be dividing every 30 minutes.

After cooking, meats are free of bacteria, but leaving them warm for an extended time will invite new bacteria to settle in and grow. For this reason, smoked and subsequently cooked meats are submitted to cold showers to pass through the “danger zone” - 40-140° F (4-60° C) as fast as possible.

Good Manufacturing Practices to Apply in the Everyday Kitchen

Homemade meats and sausages are subject to the ambient temperature of the kitchen, and a dose of common sense is of invaluable help:

- Take only what you need from the cooler.

- When a part of the meat is processed, put it back into the cooler.

- Keep your equipment clean and cold.

- Work as fast as possible.

- Try always to keep meat refrigerated.

- If your premises are not temperature controlled, limit your production to late evening or early morning hours.

- Wash your hands often.

The above measures increase our defense against the growth of bacteria, By adhering to those simple recommendations, we greatly increase our chances of producing quality meats and sausages.