Meats and Sausages

How to Render Lard Commercially

Fat trimmings for lard should be kept in the cooler and lard should be made as soon as possible. Always cut the rinds off the fat as they will lower the quality of the lard.

1. Grind fat pieces through a small grinder plate. Partially freezing fat trimmings makes the operation easier. The smaller the grind, the faster the oil is released by the fat. You could cut the fat trimmings by hand, but this is slower.

2. Get a large kettle and put water in. Use ¾ cup of water per 2.2 (1 kg) of ground fat. The water prevents the lard from scorching. Add all fat and slowly apply the heat. The kettle should be filled no more than three-fourths full. Slow is the word; apply the heat gently in order to melt some fat, and then you can turn the heat up, however, be aware that the lard tends to be darker when the heat is applied too rapidly. The cooking process will take about 90 minutes.

Using a draining spoon, skim out all the cracklings and any impurities from the surface. Butchers ran the cracklings through a lard press to squeeze out all the oil, which is added to that in the kettle.

3. Pour the lard through a piece of cheese cloth into a collecting tank, known as the settling tank.

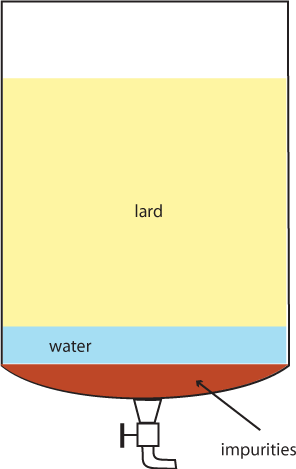

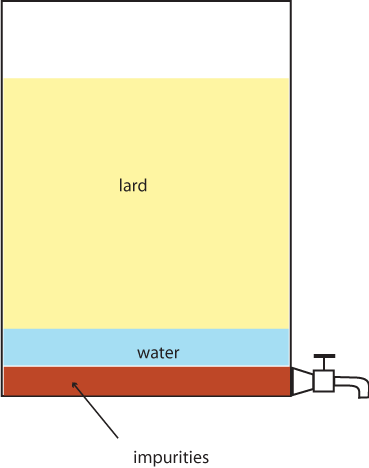

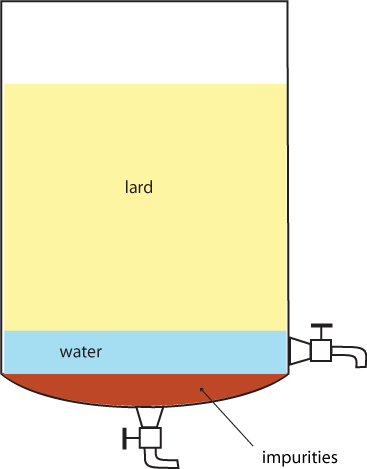

The collecting tank can have a dome-shaped bottom with a large faucet at the bottom, or the bottom can be flat with the faucet installed close to the bottom.

In this solution the water and impurities are drained through the side faucet. The tank has to be tilted so the water or lard will drain out completely. Water is heavier than oil, so the water will drain out first.

The best settling tanks were equipped with two faucets: one on the bottom for draining water and impurities and another faucet about one inch higher on the side of the tank for draining lard.

A. Let the lard settle for 1-2 hours in the settling tank. The water and solid impurities will settle at the bottom and they will be drawn off first. Now, the lard can be drawn off into containers which should be kept on ice to cool faster.

B. (Second option). Allow lard to settle in a tank for 1-2 hours and draw off the water and impurities. Stir lard with a large paddle until it is creamy and thick and then place into buckets or jars. Such lard will have a better presentation than lard that was poured into containers hot. Cool the containers.

Equipment

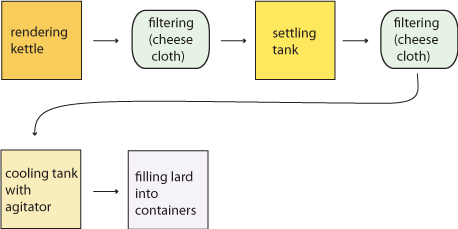

To render the best quality lard professional butchers used the following equipment:

- Rendering kettle. The lard is heated and melted.

- Settling tank. Water and impurities accumulate at the bottom. There are always small burnt tissues that cannot be easily filtered, however, they will sink to the bottom of the tank.

- Lard cooler with an agitator. The agitator is a propeller-type paddle that is turned by a manual crank or the motor. The lard is mixed until creamy and white. The good lard cooler and agitator unit are double jacketed so that cold water can be run between the walls to cool the lard.

A typical small lard rendering operation.

A practical way is to set up a settling tank above the cooler/agitator unit, so the lard can be drawn out of the settling tank into the agitator. The cooler/agitator unit must be set high enough from the floor for the lard to run into storage containers.

Compound Lard

In hot climates, lard may be too soft to handle. The problem can be corrected by mixing pork lard with 10-20% of beef tallow (rendered beef fat) or adding stearin* (see notes below). Both ingredients are available on the Internet. You can make your own beef tallow from beef suet and beef fat trimmed from steaks, and other cuts. Grind and render beef fat using the outlined above lard making procedure.

Mix all components together and agitate before placing them in containers. If no agitator is available, mix by hand until it is creamy and thick as before. Fill stiff and cool compound lard into containers.

Notes:

- If the tank has no faucet at the bottom, dip out the lard from the top without disturbing any water that will be at the bottom. Then, fill the bucket with the remaining lard and water and cool which will harden the lard. The hardened lard will float on the top of the water and can be easily taken off.

- If you have no cooling tank with an agitator, you may stir the lard by hand occasionally until it gets thick and creamy, and then run it into containers.

- The rinds can be frozen and used for head cheese or liver and blood sausages.

- *Stearin is obtained from animal fats created as a byproduct of processing beef. It can also be found in tropical plants such as palm. It is used as a hardening agent in the manufacture of candles and soap. Tallow stearin is produced from beef raw materials. It is a highly stable fat suitable for feed applications, soap production, and candles.

- The high-quality lard is filtered through the cheese cloth, separated from water and impurities, mixed, and cooled. Such lard will last a long time