Meats and Sausages

Microbiology and Safety of Canned Food

Understanding microbiology and safety of canned food is of utmost importance in home canning. Canning of jams is a very simple and well known process. It has been practiced for generations, it requires basic skills and equipment and it has been safely performed all over the world. But home canning of meat, poultry, fish and vegetables is a more involved process that requires a sound understanding of microbiology and basic principles of physics. The fact that your grandmother processed meat and preserves in the same water boiling pot, does not mean she did it right! She did it wrong but she was lucky, and nobody in the family died. However, many people had less luck and their obituary said: "died of natural causes" as that was the only explanation that the doctor could think of at the time. Having said that, we have to mention now that there are two completely different methods of canning foods and they both require different temperatures, times and equipment. The same glass jar or can may be used for both processes but the processes are entirely different.

- High-Acid Foods - jams, jellies, juices.

- Low-Acid Foods - meat, poultry, fish, vegetables.

The commercial production of low-acid foods is highly regulated by the Food and Drug Administration (FDA) and the United States Department of Agriculture, Food Safety and Inspection Service and rightly so, because people get sick and die. Even with all those regulations we have a few massive recalls of processed foods every year. And if you check the headlines, the recalled foods were not jams, juices or preserves, but they were either meats or vegetables. Ever heard of anybody getting sick from orange marmalade? The logical question arises as to what makes those low-acid foods so special? Well, the explanation is very simple, but it requires an understanding of a few basic concepts of microbiology. In other words, those tiny, invisible to the naked eye microorganisms decide how the food must be processed.

Safety of Canned Foods

Food begins to spoil soon after it is harvested or slaughtered. This spoilage is caused by microorganisms or by internal chemical changes which are caused by enzymes. Microorganisms can be destroyed and enzymes can be deactivated by heat treatment and this is the reason why thermal processing is the focal point in canning technology. Bacteria types vary and display different preferences for temperature at which they will grow or die. Understanding bacteria behavior is crucial for a better understanding of heating and cooling processes. Microorganisms such as molds, yeasts and bacteria spoil food, even at refrigerator temperatures. It is quite obvious that we have to do something special to canned food if it is to remain for 2-3 years without refrigeration. If not killed the microorganisms will find the moisture and nutrients inside of the canned food and they will multiply. Some bacteria will simply spoil the food, others might produce toxins. Clearly, we have to protect ourselves and either kill the bacteria or create such conditions that they will be unable to grow.

Food safety is nothing else but the control of bacteria. To control them effectively we have to first learn how bacteria behave. Let's make something clear, it is impossible to eliminate bacteria altogether. Life on the planet will come to a halt. They are everywhere; on the floor, on walls, in the air, on our hands and all they need to grow is moisture, nutrients and warm temperature. They all share one thing in common: they want to live and given the proper conditions they will start multiplying. They don't grow bigger, they just divide and divide and divide until there is nothing for them to eat, or until conditions become so unfavorable that they stop multiplying and die.

Microorganisms can be divided into three groups:

- Molds - are easy to kill and most will die below the temperature of boiling water; they are of little concern when canning meats.

- Yeasts - are easy to kill and most will die below the temperature of boiling water; they are of little concern when canning meats.

- Bacteria - those microorganism can be dangerous and must be properly dealt with.

It is commonly believed that the presence of bacteria creates immense danger to us but this belief is far from the truth. The fact is that a very small percentage of bacteria can place us in any danger, and most of us with a healthy immune system are able to fight them off.

Bacteria Growth in Time

Under the correct conditions, bacteria reproduce rapidly and the populations can grow very large. Temperature and time are the factors that affect bacterial growth the most. Below 45° F bacteria grow slowly and at temperatures above 140° F they start to die. In the so called "danger zone" between 40-140° F many bacteria grow very well. For instance, the infamous E.coli grows best at 98° F (37° C) and Staph.aureus at 86°-98° (30-37° C). When bacteria grow, they divide and increase in numbers, not in size. Looking at the table it becomes clear what happens to a piece of meat left on the kitchen table on a beautiful and hot summer day.

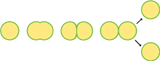

Bacteria growth. A bacteria cell enlarges in size, then a wall separates the cell into two new cells exactly alike.

| # Bacteria | Elapsed Time |

|---|---|

| 10 | 0 |

| 20 | 20 minutes |

| 40 | 40 minutes |

| 80 | 1 hour |

| 160 | 1 hour 20 min |

| 320 | 1 hour 40 min |

| 640 | 2 hours |

| 1280 | 2 hours 20 min |

| 2560 | 2 hours 40 min |

| 5120 | 3 hours |

| 10,240 | 3 hours 20 min |

| 20,480 | 3 hours 40 min |

| 40,960 | 4 hours |

| 81,920 | 4 hours 20 min |

| 163,840 | 4 hours 40 min |

| 327,680 | 5 hours |

| 655,360 | 5 hours 20 min |

| 1,310,720 | 5 hours 40 min |

| 2,621,440 | 6 hours |

Bacteria Growth With Temperature

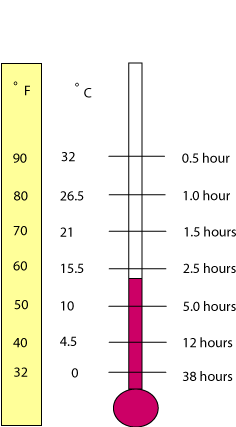

It can be seen on the graph that at 32° F (0° C) bacteria needs as much as 38 hours to divide in two. That also means that if our piece of meat had a certain amount of bacteria on its surface, after 38 hours of lying in a refrigerator the amount of bacteria will double. If we move this meat from the refrigerator to a room having a temperature of 80° F (26.5° C), the bacteria will divide every hour (12 times faster). At 90° F they will be dividing every 30 minutes. Someone might say: why do I have to bother with all this bacteria stuff, I am going to kill them anyhow. Well, this is not entirely true, as thermophillic bacteria can survive high temperatures and might spoil the food if certain procedures are not observed. Secondly, if we let spoilage bacteria multiply, for example keeping meat at room temperature for too long, they will spoil the food. The food may not exhibit odor or slime yet, but its flavor is already affected. A thermal process will kill them but the fact remains that they have already done some damage.

Bacteria growth with temperature.

Food Spoilage Bacteria

How Do Bacteria Spoil Food? Microorganisms, like all living creatures must eat. Spoilage bacteria break down meat proteins and fats causing food to deteriorate and develop unpleasant odors, tastes, and textures. Fruits and vegetables get mushy or slimy and meat develops a bad odor. They don't use the toilet, but they excrete the waste which we eat and this is the unpleasantly tasting "spoilage." Most people would not eat spoiled food. However, if they did, they probably would not get seriously sick. Bacteria such as Pseudomonas spp. or Brochotrix thermosphacta cause slime, discoloration and odors but don't produce toxins. There are different spoilage bacteria and each reproduces at specific temperatures. Some can grow at low temperatures in the refrigerator or freezer. Others grow well at room temperature and in the "Danger Zone" (40-140° F, 4-60° C).

Most spoilage bacteria are easily killed by the temperature of boiling water, 212° F, 100° C. However, there are heat loving thermophillic bacteria which are so heat resistant that their spores can survive long exposure to the temperatures of 250° F, 121° C. They like to grow at 122-150° F, 50-66° C and this can create storage problems. If bacterial spores survive thermal treatment, they might find favorable conditions to grow upon slow cooling (122-150° F, 50-66° C). For that reason, commercial producers cool containers as fast as possible to about 95° F (35° C). Very high storage temperatures, for example in tropical countries, will also create favorable conditions for their growth. To completely eliminate thermophillic bacteria the thermal process must be performed at temperatures even higher than 250° F, 121° C. A point must be made here that thermophillic bacteria may spoil the food, but they do not produce toxins and do not affect food safety. Because of that, they are not classified as a pathogenic type.

Beneficial Bacteria

Without beneficial bacteria it would not be possible to make fermented sausages, sauerkraut, yogurt or cheeses. They are naturally occurring in the meat but in many cases they are added into the meat in the form of starter cultures. There are two classes of beneficial (friendly) bacteria:

- Lactic acid producing bacteria - Lactobacillus, Pediococcus.

- Color and flavor forming bacteria - Staphylococcus, Kocuria (previously known as Micrococcus).

They are easy to kill and most will die below the temperature of boiling water; they are of little concern when canning meats.

Pathogenic Bacteria

Pathogenic bacteria cause illness. They grow rapidly in the Danger Zone - the temperatures between 40 and 140° F - and do not generally affect the taste, smell, or appearance of food. Most pathogenic bacteria, including Salmonella, E.coli 0157:H7, Listeria monocytogenes, and Campylobacter, can be fairly easily destroyed using a mild cooking process.

Safety of Canned Products - It All About Clostridium Botulinum

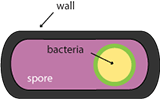

The term Clostridium means that the organism is able to grow in the absence of air and is a sporeformer. Home canned foods are the main source of botulinum food poisoning, however, two hundred years ago the canning process was still being developed. Now we finally know that the biggest enemy of canned foods is Clostridium botulinum, a dangerous heat resistant microorganism which does not need oxygen to grow. If a canned product does not receive proper heat treatment, there is an increased risk that Cl.botulinum could survive and produce toxin within a container. The toxin attacks the nervous system and one millionth of a gram will kill a person. This means that 1 kg (2.2 lb) could kill 1 billion people on earth, clearly the strongest poison known to man. Fortunately, we are seldom exposed to Cl. botulinum bacteria in their "vegetative" (growing) phase when they produce toxin. However, we find those bacteria in the form of bacterial spores in water and soil everywhere. Whenever a spore forming bacteria feels threatened, it will immediately build a protective wall around itself in the form of a cocoon. This shell is built within a few hours.

Because Cl.botulinum hate oxygen, the air which is present in soil and water threatens them. Cl.botulinum bacteria immediately envelop themselves within a protective shell. They don't multiply, they just patiently remain inside waiting for more favorable conditions. Similarly to plant seeds, they can survive harmlessly in soil and water for many years. Then when the opportunity arises, they emerge from their shells and become vegetative bacteria (actively growing). During this growing stage they produce toxin. It is the toxin that kills, not the bacteria. Where most bacteria can be killed at 160° F (72° C), Cl. botulinum is protected inside of the spore and will survive the temperature of boiling water (212° F, 100° C) for 5 hours. Processing meat for so long will result in a poor texture, flavor and color. For this reason low acid foods must be processed in a pressure canner at 240° F (116° C) as this temperature will kill botulinum spores in about 2 minutes. If spores are not completely killed in canned foods, vegetative microorganisms will grow from the spores as soon as conditions are favorable again. Vegetative cells will multiply rapidly and may produce a deadly toxin within 3 to 4 days of growth in an environment consisting of:

- A moist, low-acid food.

- A temperature between 40-120° F (4-40° C).

- Less than 2% oxygen.

All of the above conditions are met in a canned food. Any surviving microorganisms can either spoil the canned food or produce toxins which cause food poisoning. It is of absolute importance that food manufacturers implement policies that would prevent such an occurrence. And they do, however, home canners are not aware of the danger and often use procedures which are correct for making jams, but are completely wrong for processing meats or vegetables.

Most bacteria, yeasts, and molds are difficult to remove from food surfaces. Washing fresh food reduces their numbers only slightly. Peeling root crops, underground stem crops, and tomatoes reduces their numbers greatly. It would be ideal to apply very high temperatures which would eliminate all microorganisms, once and for all. However, such a heat treatment will degrade the quality of some foods and will lower their nutritional value. A compromise is reached to keep the sterilization temperatures high enough to ensure safety of the products and low enough to produce quality products. The concept of heat treatment is introduced which is a combination of two components:

- Heating temperature.

- Heating time.

The same amount of heat treatment can be obtained when using lower temperature supported by a longer heating time OR higher temperature supported by a shorter heating time. It is easier to kill bacterial spores when the canning temperature is increased. The reference temperature of 250° F (121° C) and reference time of one minute is chosen. The amount of heat which is delivered at 250° F (121° C), during one minute is defined as F-value-1. F-value for killing Cl. botulinum spores is 2.52, which means that the spores are deactivated when submitted to 2.52 minutes of heating time at 250° F (121° C). This F-value of 2.5 for C. botulinum spores is known as "botulinum cook."

| Time and Temperature Needed to Deactivate Cl. botulinum Spores | ||

|---|---|---|

| 214° F, 101° C | 232° F, 111° C | 250° F, 121° C |

| 250 min | 25 min | 2.5 min |

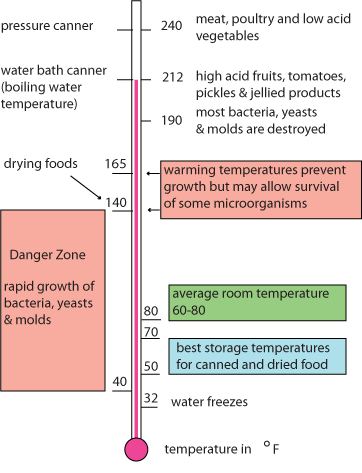

Temperatures for food preservation.

We ensure food safety with:

- Pasteurization, 149-203° F (65-95° C). Pasteurization kills pathogenic bacteria and is adequate for foods that would be refrigerated. Typically, high acid foods or acidified foods (added vinegar, lemon juice) with a pH < 4.5 are pasteurized.

- Sterilization, 221-266° F (105-130° C). Sterilization method makes indefinite product life at ambient temperatures. Typically, low acid foods with a pH > 4.5 are sterilized.

- Blanching also helps, but the vital controls are the method of canning and making sure the recommended heating temperatures and times are used. The processing times in USDA guides ensure destruction of the largest expected number of heat-resistant microorganisms. Properly sterilized canned food will be free of spoilage if lids seal and jars are stored below 95° F (35° C). Storing jars at 50-70° F (10-21° C) enhances the retention of quality.

Why Canned Foods Offer Favorable Conditions for the Growth of Cl. botulinum?

Cl.botulinum do not grow in the presence of air, so we are not at risk when cooking meats with usual cooking methods. However, bacterial spores do not die, they remain in a dormant stage, enveloped in their protective shells until conditions become favorable for their growth. This happens when there is no more oxygen (air) and this is exactly what happens during canning when most of the available air is exhausted from the container. In order to form a strong vacuum inside of the container, as much air as possible is removed. This creates a stronger seal and leaves room for the expansion of gasses. Without a vacuum, the cans will buckle and the contents of a jar may boil over through the seal. In a hermetically sealed container bacterial spores find the right temperature, plenty of moisture and nutrients, and the absence of air. Bacteria leave the spore and germinate. They start growing and produce toxin.

Control of Cl. botulinum

There are two ways of controlling Cl. botulinum:

- Killing spores.

- Preventing spores from germinating and growing.

Spores of Cl.botulinum are present in both acid and low-acid foods. In low acid-foods such as meats and vegetables, Cl.botulinum spores can only be killed at 240° F, 116° C or higher. However, the high acidity (pH < 4.6) prevents botulinum bacteria from leaving the spores. This prevents them from germinating and growing, and of course no toxin is produced. For this reason high-acid foods such as fruits or juices can be processed at 212° F, (100° C) as this temperature will kill all bacteria in vegetative form and bacterial spores are prevented from germinating by high acidity. The growth of Cl.botulinum is inhibited at 10% salt concentration which is equivalent to a water activity of around 0.93. Obviously, such high salt percentages will not be tolerated by a consumer.

Inactivating Toxin

The toxin is not heat resistant; it can be inactivated by boiling in water (212° F 100° C) for 10 minutes. Old canning manuals often asked for boiling home canned meats and vegetables for 10-15 minutes in an open vessel. This procedure was meant to destroy any bacteria or toxins that might have survived the incorrect canning process.

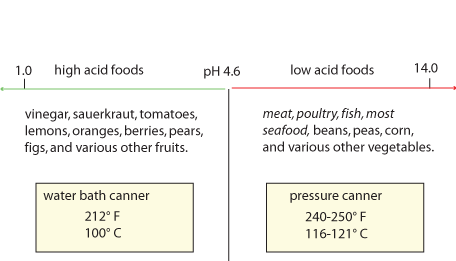

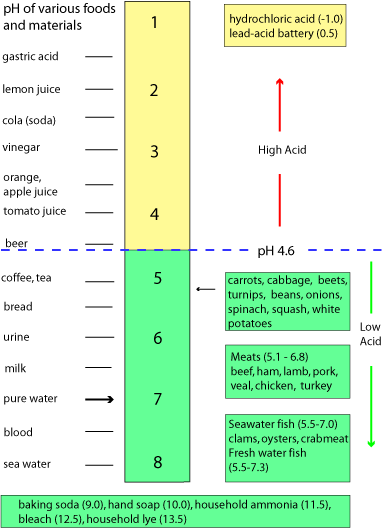

pH Acidity and Processing Methods

The main objective of thermal processing is control of Cl.botulinum bacteria. Whether food should be processed in a pressure canner or boiling-water canner depends on the acidity of the food. The term "pH" is a measure of acidity; the lower its value, the more acidic the food. Bacteria hate acidity, this fact works to our advantage. Acidity may be natural, as in most fruits, or added, as in pickled food. The acidity level in foods can be increased by adding lemon juice, citric acid, or vinegar. All bacteria have their own preferred acidity level for growth, generally around neutral pH (7.0). Bacteria will not grow when the pH is below the minimum or above the maximum limit for a particular bacteria strain. As the pH of foods can be adjusted, this procedure becomes a potent weapon for the control of Cl.botulinum. The thermal resistance of microorganisms decreases as the pH of their medium is lowered. As explained earlier, most bacteria, particularly Cl. botulinum, will not grow below pH 4.6. Therefore acidic foods having pH below 4.6 do not require as severe heat treatment as those with pH above 4.6 (low acid) to achieve microbiological safety. The pH value of 4.6 is the division between high acid foods and low acid foods. Low-acid foods have pH values higher than 4.6. They include red meats, seafood, poultry, milk, and all fresh vegetables except for most tomatoes.

Processing methods for low and high acid foods.

Most mixtures of low-acid and acid foods also have pH values above 4.6 unless their recipes include enough lemon juice, citric acid, or vinegar to make them acid foods. Acid foods have a pH of 4.6 or lower. They include fruits, pickles, sauerkraut, jams, jellies, marmalades, and fruit butters.

pH of various foods and materials. A lower pH value indicates higher acidity.

Although tomatoes generally fall on the pH dividing line at 4.6, there are varieties that have a lower pH level and there are varieties which also have a higher pH level. Tomatoes are usually considered an acid food. Figs also have pH values slightly above 4.6. Therefore, if they are to be canned as acid foods, these products must be acidified to a pH of 4.6 or lower with lemon juice, citric acid or vinegar. Properly acidified tomatoes and figs are acid foods and can be safely processed in a boiling-water canner. However, changing acidity levels requires a good understanding of food technology and should be left to professionals. In addition, not all foods will appeal to a consumer when their flavor is overly acidic.

pH Meters

There are many companies making pH measuring equipment. Large bench models are expensive and will be used by the professionals who establish thermal processes for canned foods. We have been using the Hanna Instruments HI 99163 Meat pH Meter with much satisfaction for making fermented sausages. The instrument is of great value for the pH analysis of meat products. This pH meter is simple to use with only two buttons. The replaceable penetration blade allows the user to measure not only the surface, but also the internal pH of the meat. The unit is very accurate and the reading is obtained within seconds.

- Specifications:

- Range pH - 2.00 to 16.00 pH

- Range Temperature - 5.0 to 105.0° C / 23.0 to 221.0° F

- Resolution pH 0.01 pH

- Resolution Temperature 0.1° C / 0.1° F

- Accuracy pH ± 0.02 pH

Control of Bacteria by Water Activity

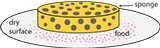

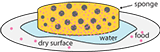

In order to remain alive the microorganisms need nutrients and moisture. How do bacteria eat? Imagine some sugar, flour or bread crumbs spilled on the table. Place a dry sponge on top of the sugar and you will see that the sponge will not pick up any of the ingredients. Pour some water over the ingredients and repeat the sponge procedure. The sponge will absorb the solution without any difficulty. Bacteria are like a sponge, they absorb food through the wall, but the food must be in a form of a solution. It must contain water. When water is eliminated, bacteria cannot eat.

All microorganisms need water and the amount of water available to them is defined as water activity. Water activity (Aw) is an indication of how tightly water is "bound" inside of a product. It does not say how much water is there, but how much water is available to support the growth of bacteria, yeasts or molds. Adding salt or sugar "binds" some of this free water inside of the product and lowers the amount of available water to bacteria which inhibits their growth. The most practical approach for lowering water activity is drying, although it is a slow process which must be carefully monitored, otherwise it may backfire and ruin the product. A simple scale is used to classify foods by their water activity and it starts at 0 (bone dry) and ends on 1 (pure water).

Below certain Aw levels, microbes can not grow. USDA guidelines state: "A potentially hazardous food does not include... a food with a water activity value of 0.85 or less."

| Water activity (Aw) of some foods | |

|---|---|

| Pure water | 1.00 |

| Fresh meat & fish | 0.99 |

| Bread | 0.99 |

| Salami | 0.87 |

| Aged cheese | 0.85 |

| Jams & jellies | 0.80 |

| Plum pudding | 0.80 |

| Dried fruits | 0.60 |

| Biscuits | 0.30 |

| Milk powder | 0.20 |

| Instant coffee | 0.20 |

| Bone dry | 0.00 |

Meats, dried fruits and vegetables were preserved throughout our history and the technology was based on simple techniques of salting and drying. It was also discovered that the addition of sugar would preserve foods such as candies and jellies. Both factors contribute to lowering the water activity of the meat. Freshly minced meat possesses a very high water activity level around 0.99, which is a breeding ground for bacteria. Adding salt to meat drops this value immediately to 0.96-0.98 (depending on the amount of salt), and this already creates a hurdle against the growth of bacteria. This may be hard to comprehend as we know that water does not suddenly evaporate when salt is added to meat. Well, this is where the concept of water activity becomes useful.

Although the addition of salt to meat does not force water to evaporate, it does something similar: it immobilizes free water and prevents it from reacting with anything else, including bacteria. It is like stealing food from the bacteria, the salt locks up the water creating less favorable conditions for bacteria to grow and prosper. As we add more salt, more free water is immobilized but a compromise must be reached, as adding too much salt will make the product unpalatable. It may also impede the growth of friendly bacteria, the ones which work with us to ferment the sausage. The same happens when we freeze meat though we never think of it. Frozen water takes the shape of solid ice crystals and is not free anymore. Water exists in meat as:

- Bound (restricted or immobilized water) - structurally associated with meat proteins, membranes and connective tissues. This water (3-5% of total water) can only be removed by high heat and is not available for microbial activities.

- Free or bulk water - held only by weak forces such as capillary action. This free water is available for microorganisms for growth.

Removing water content by drying food has been practiced for centuries. As the process proceeds, water starts to evaporate (water activity decreases), making meat stronger against spoilage and pathogenic bacteria. There eventually comes a point where there are no bacteria present and the meat is microbiologically stable. It will not spoil, as long as it is kept at low temperatures and at low humidity levels. If the temperature and humidity go up, new bacteria will establish a colony on the surface and will start moving towards the inside of the sausage. The mold will then immediately appear on the surface. Microbial spoilage is a frequent cause of spoiled foods or defective containers. It may result from:

- Holding containers too long before processing.

- Contamination after processing.

- Inadequate thermal process.

- Inadequate cooling of the containers or storage at high temperatures.

- Spoilage due to survival of acid-tolerant spores (flat sour).

| Minimum Aw requirements for microorganism growth | |

|---|---|

| Molds | 0.75 |

| Staphylococcus aureus | 0.85 |

| Yeasts | 0.88 |

| Listeria | 0.92 |

| Salmonella | 0.93 |

| Cl. botulinum | 0.93 |

| E.coli | 0.95 |

| Campylobacter | 0.98 |

Water Activity Meters

- Resolution: plus, minus 0.01 Aw.

- Accuracy: plus, minus 0.02 Aw.

- Case dimensions: 3.5" x 4"

- Weight: 115 g (4 oz).

- Photo courtesy Decagon Devices Inc.

- www.decagon.com

Summary

Botulinum spores are very hard to destroy at boiling-water temperatures; the higher the canner temperature, the more easily they are destroyed. Therefore, all low-acid foods should be sterilized at temperatures of 240-250° F, 116-121° C, attainable with pressure canners operated at 10 to 15 PSIG (PSI). PSIG means pounds per square inch of pressure as measured by gauge. At temperatures of 240-250° F, 116-121° C, the time needed to destroy bacteria in low-acid canned food ranges from 20 to 100 minutes. The exact time depends on the kind of food being canned, the way it is packed into jars, and the size of the jars. The time needed to safely process low-acid foods in a boiling-water canner ranges from 7 to 11 hours; the time needed to process acid foods in boiling water varies from 5 to 85 minutes.

The USDA recommends that most meats are cooked to 160° F, 72° C internal temperature so a question may be given why canned meats must be processed to 240-250° F, 116-121° C. Well, cooking meats to 160° F, 72° C internal meat temperature kills ordinary bacteria so the meat is considered safe to eat, but be aware that bacterial spores will survive. Because they are in continuous contact with air, they will not germinate and will not produce toxin. You might eat them, but that will not create danger, after all we eat bacteria in sauerkraut, salami, cheese and yoghurt all the time.