Meats and Sausages

Equipment for Making Fermented Sausages

Making fermented sausages at home, definitely presents some difficulties, which we don’t face when making other types of sausages. To be able to precisely control temperature, humidity, and airspeed requires expensive, computer-controlled drying chambers; hence, a home sausage maker must use his ingenuity to come up with suitable solutions. It is helpful to have a system capable of automated temperature and humidity adjustments, but those with limited funds need to improvise a bit. Without a doubt, the precise control of such a vast range of temperatures (10-40º C, 50-104º F) and humidity (60-95%) is not easy.

There are no small drying chambers designed for home production of fermented sausages, so one has to assemble his own system. Commercial producers use huge rooms with air conditioning ducts supplying air at the right temperature, humidity, and speed.

There is a refrigerator in every kitchen which can be easily adapted for fermenting and drying sausages. A used refrigerator can be obtained everywhere, and as long as it works it will fit our purpose. Most refrigerators are made with a separate freezer door which is normally located in the upper part of the unit. Well, this unit is not needed and will not become part of the system. If a one-door refrigerator can be found it works even better.

Temperature Control

There is a problem with the refrigerator’s temperature range as its thermostat is made to control temperatures between 0-4º C (32-40º F). Such temperatures are not needed during fermenting and drying sausages. Fortunately, there is a commonly available device called a line voltage thermostat. It is an electronic temperature control or rather a combination of a temperature sensor, switches, and electronic control which can transform an ordinary refrigerator into a wonderful drying chamber.

Line Voltage Thermostat - Single Stage

Electronic temperature control in cooler mode. The above drawing depicts a single-stage control which means that it can control only one device at a time. There are two stage units that can control a heater and a cooler from the same control. A line voltage thermostat set to "cooling mode" can only decrease temperature lower than the temperature that remains outside the refrigerator.

The refrigerator is unplugged from the outlet and is then plugged into the temperature control which is plugged into the electrical outlet. The refrigerator’s thermostat is not controlling temperature anymore and is taken over by the temperature sensor in the controller, which is inserted into the refrigerator. There is no need to drill a hole as the refrigerator door has rubber insulation and the sensor’s cable is thin. In short terms, the microprocessor monitors the temperature through the sensor and when the temperature is warmer than the set point, the processor will energize the internal relay (switch). This allows the refrigerator to draw the current from the outlet. The drawing is not to scale, and the typical unit is about: 6.5" x 2.7" x 2.5". The beauty of this setup lies in the fact that no damage is done to the refrigerator. These units can control coolers, heaters, or any electrical device.

There are instances when the temperature inside the chamber must be higher:

- Fast fermented sausages made with starter cultures which require fermentation temperatures of around 30-45º C (86 -113º F)

- The drying chamber is located in a cool climate where temperatures are below 20º C (68º F) for a larger part of the year. Under such circumstances, the same line voltage thermostat can be combined with a heater and used in the heating mode.

In such a case the temperature control is switched to "heating mode", the refrigerator is disconnected and the heater is plugged into the temperature control.

Electronic temperature control in heater mode. The refrigerator is not working but is used as a fermentation/drying chamber. Any little heating element, ceramic heater, heat lamp, or even UL-approved light fixture can easily raise the temperature in a small unit like a refrigerator. Using an ordinary light bulb is not recommended as prolonged exposure to light creates rancidity in fat.

Temperature control can be used in the heating mode during fermentation, which lasts on average about 1-2 days and even less for fast-fermented products. Then, when a product enters the drying stage, the heater can be removed and the control unit is switched back into the cooling mode.

When ambient temperatures are low and the heating mode is selected, the refrigerator can still be used as a drying chamber, even though it is disconnected from the power supply. In cooler climates, it is practical to build a large drying chamber (even a walk-in unit) from any materials, as long as good insulation is included. Then, not being limited by space, any kind of free-standing heater or humidifier can be placed inside as long as there is electricity close by. These electronic temperature controls are very precise and can maintain the set temperature within 1 degree.

Line voltage thermostat in heating mode. A drying chamber can be any type of insulated box or unit.

Line Voltage Thermostat - Two Stage

The advantage of a two-stage thermostat is that two independent devices such as a heater and a cooler or a heater and the fan can be connected to only one temperature control.

Two-stage line voltage thermostat. Two-stage temperature control offers more possibilities but comes at a higher cost.

Humidity Control

Humidity control is much harder to accomplish than temperature. All those improvised arrangements, such as placing salt covered with water in a shallow pan or bringing more water-filled pans into the chamber, may increase the humidity level to 50-60% which is nowhere close to the required humidity during fermentation. In 1975, folks at Clemson University, Clemson, Ohio came up with an interesting idea for the construction and operation of a relatively inexpensive cabinet for sausage fermentation. Temperature could be controlled to plus, minus 1º C with a relative humidity of approximately 95%.

Sausage fermentation cabinet with air temperature controlled via warm water bath heated by external heater-circulator pump.

The above design provides a constant high humidity of about 95% which is an ideal setting at the beginning of fermentation. Cabinet air temperatures above the coil-heated water of 30 and 38º C were achieved with external water bath settings at approximately 38 and 52º C. The capacity of the external tank (heater pump) was 16 liters (7.27 lbs), and the cabinet contained 25 liters of water (11.3 lbs) which covered the coil in the bottom of the cabinet. As one gallon of water weighs 8.34 lbs, these are not huge amounts of water. A separate dish may be inserted into the cabinet, as long as water covers the copper tubing. The only problem is that this cabinet has to be exclusively designated as the fermentation chamber as it provides no means for decreasing humidity. It is not possible to dry sausages at such high humidity levels.

This old but still interesting design can be improved upon by using a modern fish tank heater and the temperature controller:

Sausage fermentation cabinet with air temperature controlled via fish tank water heater and temperature controller.

Unbreakable high-wattage submersible titanium heaters come in 500 and 1000 Watts, but they need a temperature controller. Both water designs are simple to make, and they lead themselves quite well for making fast-fermented sausages (summer sausage, thuringer) which will be made with starter cultures. With such an arrangement sausages can be made at any given time (every day) and then transferred to a separate drying chamber where the process will continue.

There is an even simpler solution for making fast-fermented sausages where humidity will be at a constant 100%. A serious limitation of this design is that no lowering of humidity and no drying is possible and this method should be used for very short fermenting times only. To prevent salt migration from the sausage into the water, some salt must be added to the water or a higher amount of salt must be added to the sausage mass. Nevertheless this arrangement can be used for making fast-fermented sausages with a fast fermenting starter culture at 40ºC (104ºF) and 1% dextrose.

Fermentation in water. No cover is necessary. Under such conditions, fermentation can be accomplished in 12 hours. Then, after drying the casing, the sausage can be submitted to smoking, cooking or both. It can also be dried if additional weight loss is desired.

Adjustable Humidifiers

The simplest way to control humidity is to install a small digital adjustable humidifier. A good unit should lock to the setting within a few percent. In industrial units, increasing humidity is accomplished by steam injection but home units produce a cool vapor mist.

Adjustable humidifier. It should be noted that an average hygrometer is rated to indicate humidity plus or minus 3% at best. In reality, they are even less accurate (10%), but there are more expensive calibrated units that are accurate within 1%.

Air conditioners and refrigerators dehumidify air and the relative humidity is around 40%. This is much too low for making fermented sausages, especially at the beginning of the fermentation stage when 90-95% humidity is needed. If a sausage is fermented without humidity control, periodic spraying or immersing it in water will help a lot by providing 100% of humidity on its surface, if only for a short while.

There is a device called line voltage humidistat which basically works like the temperature controls described above. When in "humidify" mode the device will increase humidity by switching on the humidifiers. When in "dehumidify" mode the same device will switch on the fan to remove moist air from the chamber.

Single stage humidistat. This unit comes with a built-in humidity sensor and must be installed within the drying chamber.

Airspeed

To control air speed in improvised chambers such as a refrigerator is surprisingly easy. The most reliable device is the computer cooling fan as it is designed for working 24 hours a day. There is a huge variety of these fans, and they come in different sizes, shapes, and power outputs. They can be purchased online or at any computer store. The current draw of a typical 3" 12 VDC, 1.9 W fan is only 0.1 A. It runs from a 115 VAC adapter, and the beauty of the design is that the adapter’s output can be set to 12, 9, 7.5, or 6 VDC with a built-in mini switch. Each voltage setting lets the fan run at a different speed and quite a sophisticated system is created.

Adjustable airspeed fan.

Note if only fixed DC output voltage adapter is available, a simple, inexpensive and universally available device called "potentiometer" can be attached between the fan and the adapter. The device will control the fan’s speed.

Thermometers

Standard room thermometers are surprisingly accurate when placed inside the drying chamber, which can not be said about some inexpensive digital cable remotes. It is nice to have a cable remote thermometer with the display located outside of the chamber but make sure the cable looks strong and that it is jacketed. Very thin cable wires can be off the mark by a few degrees, although the problem disappears when the wire is insulated. There is no need for a separate thermometer when using the line voltage thermostat as these units are very accurate.

Separate fermentation and drying chambers

Using one chamber for fermenting and another one for drying, offers many advantages even if less precise control of temperature is achieved. Using the same chamber for fermenting and drying creates a major inconvenience when a new production must be started. Fermentation is a relatively short process and let’s say it was accomplished in 48 hours. Now the temperature and humidity should be lowered to start drying. In case we make a slow-fermented salami, the drying may continue for months.

Suddenly, the neighbor comes over and wants to make fast-fermented and cooked salami. Well, we have a little problem; and ask him to come back in a month, when salami will be finished and the chamber will be once more available. This problem can be avoided when two or three separate chambers are involved:

- Fermentation chamber

- Drying chamber

- Storing chamber

Employing one designated chamber for fermentation and another one for drying/storing allows for mixing products that were made on different days. More meats can be processed and added in time to drying chambers, for example, in the wild game hunting season. When the humidity sensor is placed inside the drying chamber, the control unit may be mounted outside, up to 20 feet away. It is insignificant whether a humidifier is adjustable, as the humidistat control will switch it on and off, provided that electricity is available

Note that designs that incorporate line voltage humidistats allow for precise control of humidity only. Temperature is set with a separate temperature controller

Humidity control plays an important role in greenhouse production of flowers and vegetables. Many clever devices can be obtained from greenhouse equipment suppliers as some exotic flowers need precise temperature and humidity monitoring.

An improvised setup - refrigerator temporarily used as a fermentation/drying chamber. No drilling is needed. Smoke sticks are attached to screens by carabiner spring clips. An ordinary twine loop will do.

Digital humidifier providing humidity. Line voltage thermostat controlling temperature precisely in "heat" mode during fermentation (barbecue starter used as a heating element) and in "cool" mode during drying (refrigerator used as a cooling device).

Measuring pH (acidity)

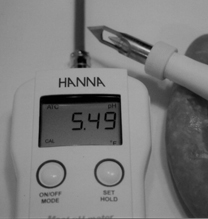

pH meat tester made by Hanna Instruments http://www.hannainst.com/usa provides an instant and accurate reading.

Specifications:

Range pH -2.00 to 16.00 pH

Range Temperature -5.0 to 105.0°C / 23.0 to 221.0°F

Resolution pH 0.01 pH

Resolution Temperature 0.1°C / 0.1°F

Accuracy pH ±0.02 pH

Temperature Compensation Automatic, -5 to 105°C (23 to 221°F)

pH Electrode FC 232D, amplified, food compatible body material, built-in temperature sensor

thread for blade insertion (included)

Environment: 0 to 50°C (32 to 122°F); RH max 100%

Dimensions: 150 x 80 x 36 mm (5.9 x 3.1 x 1.4")

Weight: 210 g (7.4 oz.)

Battery Type / Life 3 x 1.5V AA / approx. 1500 hours of continuous use: auto-off after 8 minutes of non-use

The specially designed electrode FC 232D incorporates many essential features to perform reliably without damaging the sample. This probe has a built-in temperature sensor that provides automatic temperature compensation, an open junction to avoid a clogged reference, and its external body material is non-toxic and food-compatible.

The probe body has an external thread to securely screw on the stainless steel penetration blade FC 099, included with the kit. The replaceable penetration blade allows the user to measure not only the surface but also the internal pH of the meat. Calibration is automatic at 1 or 2 points, selectable between 2 memorized buffer sets. Battery life is more than 1500 hours and the instrument automatically turns off after 8 minutes of inactivity.

pH testing paper strips made by: http://www.microessentiallab.com Micro Essential Laboratory, Inc.

To use, mix 1 part finely chopped meat and 2 parts distilled water, tear off a strip of pH paper, dip into test solution, and match immediately to color chart. No technical training is necessary.

Measuring Aw (water activity)

Below certain Aw levels, microbes can not grow. USDA guidelines state:

"A potentially hazardous food does not include . . . a food with a WATER ACTIVITY value of 0.85 or less."

Pawkit Aw measuring instrument by Decagon, http://www.decagon.com This is a lab testing device and may be too expensive for a typical hobbyist.

Paw water activity meter

Range: 0 to 1.0 Aw

Resolution: plus, minus 0.01 Aw

Accuracy: plus, minus 0.02 Aw

Case dimensions: 3.5 x 4"

Weight: 115 g (4 oz).

Pawkit uses a dielectric humidity sensor to measure the Aw of a sample. In an instrument that uses this technique, a special polymer is placed between two porous electrodes in the headspace of a sealed chamber. The electrical properties of the polymer change depending on the relative humidity of the chamber. The electrodes give a signal based on the relative humidity in the closed chamber. This signal is then translated by the software and displayed as water activity on the instrument’s screen. At equilibrium, the relative humidity of the air in the chamber is the same as the water activity of the sample. The Pawkit is accurate to ±0.02 aw. For many applications, this accuracy is more than adequate. If you require higher accuracy in your measurements, we recommend you use Decagon’s AquaLab water activity meter, which is a lab-grade, bench-top instrument that has an accuracy of ±0.003 aw.

Improvised Equipment

Although the equipment may vary in size and nature, some criteria must not be improvised upon and this is the temperature and the safety hurdles. What can be flexible is the choice of physical devices that may be selected to control specific parameters. It makes little difference whether a hot plate, barbecue starter wire, fish tank heater, soldering iron, or an electrical bulb will be used to raise the temperature, as long as the correct temperature is maintained.

Fermented sausages can be made in any kitchen, and a stove or baking oven can be used as a drying chamber, as long as it is big enough to accommodate hanging sausages. Depending on the insulation of the unit, different heat sources may be employed, even internal light will do. The temperature can be controlled by simply switching the light bulb on (20º C, 68º F) and off (25º C (77º F). When making fast-fermented sausages with cultures, the optimum fermentation temperature will be higher. That does not mean that fermentation will not take place at a lower temperature. It will, but it will progress much slower. The fermentation (with starter culture) should be completed in 2 days at 24º C (75º F) and humidity 85-90%. This is a high level of humidity which is present only in humid tropical climates or just after the rain. In an air-conditioned room, the humidity level is only about 40%, so it is ill-suited for fermentation, drying, or even prolonged storage. Controlling temperature is easy, and there are countless heating devices that would perform the task, but to adjust humidity one needs a humidistat control or adjustable humidifier. Then, sausages enter the drying stage which continues for about 20 days. The temperature and humidity should be gradually lowered (if possible) about 1º C and 4 % humidity drop every 5 days. By doing this, we finish the drying process at about 16º C (60 F) and 70-75% humidity. Fast and medium-fermented sausages will be done now. During the beginning of fermentation, the humidity in the chamber is at high levels and is the sum of the moisture in the air, the moisture that is created by placing a water-filled pan inside of a chamber, and the moisture that evaporates from the sausages. As the fermentation and drying cycles progress, less moisture will be removed from the sausages and the relative humidity of the chamber will decrease.

In the past, when sausages were made in natural conditions, control of humidity was an ever-present problem; strategically placed openings were either opened or closed. Water was manually sprayed into suction vents or wetted rags were placed there. That required a lot of experience and was labor intensive. Today, the availability of temperature and humidity controllers makes this task possible and easy to perform at home. Were it not for those technological breakthroughs and the availability of testing equipment and starter cultures, this page would probably not be written.

More About Cold Smoking

Most semi-dry sausages are smoked, many with cold smoke. In the past, smoking was firstly a preservation step with the benefit of better flavor. Today, cold smoking is seldom performed as a preservation step due to the widespread use of refrigeration. Some foods, notably cold smoked salmon (lox) are still made with cold smoke but the majority of regular sausages are hot smoked today. Think of cold smoke as a part of the drying/fermentation cycle and not as the flavoring step. If the temperature of the smoke is close to the fermentation temperature, there is very little difference between the two. The sausage will still ferment, and the drying will continue; the extra benefit is the prevention of mold that would normally accumulate on the surface. Cold smoking is performed with a dry, thin smoke. If we applied heavy smoke for a long time, that would inhibit the growth of color and flavor-forming bacteria which are so important for the development of flavor in slow-fermented sausages (salamis). As drying continues for a long time and cold smoking is a part of it, it makes little difference whether cold smoke is interrupted and then re-applied again. In traditional smokehouses the fire was started in the morning and burning logs produced smoke until late night hours until the fire died out. Then it was re-ignited again and the smoke continued. The drying temperature falls into 15-18º C (59-64º F) range and cold smoke (< 22º C, 72º F) fits nicely into this range. To sum it up, the length of cold smoking is loosely defined, but the upper temperature should remain below 22º C (72º F).

Unfortunately, this rule puts some restraints on making slow-fermented sausages in hot climates for most of the year, when using an outside smokehouse. You can’t produce cooler smoke than the ambient temperature around the smokehouse, unless some cooling methods are devised. By the same token, people living in cooler climates can make those sausages for most of the year. Semi-dry sausages, which are of fast-fermented type, are fermented at higher temperatures. These sausages can be smoked with warmer smoke as they are subsequently cooked.

More About Humidity Control

It takes a day or two to get to know your adjustable humidifier. When fermentation starts, humidity should be high (> 90%), but set your humidifier lower, at about 75%, and see what will happen in an hour or two. Evaporating moisture from the sausages should increase the humidity inside your fermentation chamber to about 90% or higher. Open the door periodically to let the moisture out (do some fanning with a magazine), and humidity will fall down, let’s say to 80%.

Close the door and check it again to see the humidity level. Were you to set up your humidity at 90% or higher, the evaporating moisture from the sausages will soon saturate the chamber and the sausages will be soaking wet. The door should be opened and the chamber dehumidified. When drying sausages do the same, set your humidifier at 60% and see how humid the drying chamber becomes. As the sausage loses more moisture, these changes will be less pronounced and a point will be reached when humidity in the chamber will be a little higher than the setting of the humidifier.

In closed chambers such as modified refrigerators, there is no ingress nor egress of the air, so the evaporating moisture from the sausages will increase the humidity in the chamber. The fan facilitates drying but it moves the same air around. That is why the door will have to be periodically opened to let this moisture out. If an opening could be made, a fan controlled by a humidistat switched to "dehumidify" mode would remove moist air outside. In commercial chambers, the air with preset temperature and humidity is blown into the room and sucked out at the other side.

Weighing Cultures and Spices

A digital scale like the one in the photo is of immense value for those who are serious about making quality sausages. Starter cultures come in little packets and 25 g of T-SPX will ferment 200 kg (440 lb) of meat. 5 lbs of meat (the size of a pork butt) needs just 0.28 g (0.001 oz) of culture. It can be roughly estimated to be a 1/8 of a teaspoon but this is not a scientific way at all. Spices are normally added at about 1-2 g per 1 kg (2.2 lb) of meat which may correspond to 1-2 flat teaspoons. There are different sizes of teaspoons in the USA and Europe and the same recipe becomes a different recipe depending on the size of a measuring device. The only consistent method of applying ingredients is to weigh them on an accurate scale. Gun powder reloading scales are the best and American Weigh Systems make some wonderful units.